2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers

In the ever-evolving landscape of manufacturing, the mill turn machine has emerged as a groundbreaking solution that combines milling and turning operations into a single, efficient process. As global demand for precision engineering continues to rise, reports indicate that the market for CNC machining centers, including mill turn machines, is projected to increase by approximately 7.5% annually, reaching a valuation of over $6 billion by 2025. This growth is driven by advancements in technology, as well as the need for manufacturers to enhance productivity and reduce operational costs. In 2024, understanding the best mill turn machines available in the market is crucial for industry players looking to stay competitive. This comprehensive guide will navigate through the latest innovations, key features, and buyer considerations, empowering global buyers to make informed decisions that align with their manufacturing needs.

Top Mill Turn Machines: Key Features and Global Appeal

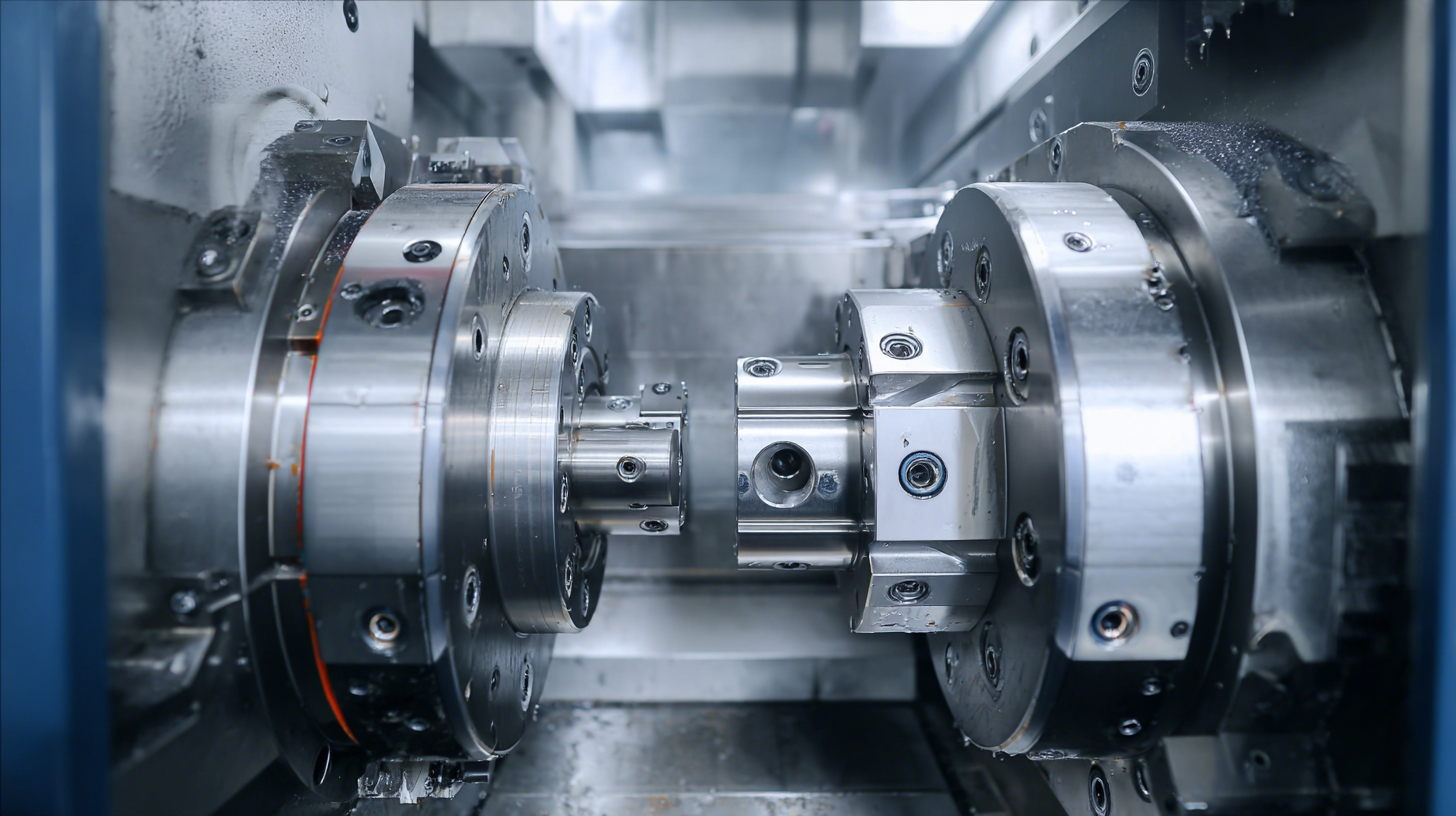

When exploring the landscape of mill turn machines, understanding their key features is essential for global buyers. Mill turn machines combine milling and turning functionalities, allowing for exceptional versatility and efficiency in machining. One of the standout features is their ability to perform complex geometries in a single setup, significantly reducing cycle time and increasing productivity. Additionally, advanced control systems and user-friendly interfaces enhance operation precision, making them accessible even for less experienced operators.

Global appeal is another critical aspect driving the popularity of these machines. Manufacturers around the world are recognizing the demand for high-quality, reliable equipment that can adapt to various materials and project requirements. This adaptability is particularly relevant in industries such as aerospace, automotive, and medical device manufacturing, where precision and efficiency are paramount. Furthermore, the integration of IoT technology in modern mill turn machines allows for real-time monitoring and predictive maintenance, enhancing operational efficiency and minimizing downtime. As businesses continue to expand globally, the need for advanced machining solutions, like mill turn machines, becomes increasingly important in staying competitive in the global market.

Understanding the Technology Behind Mill Turn Machines

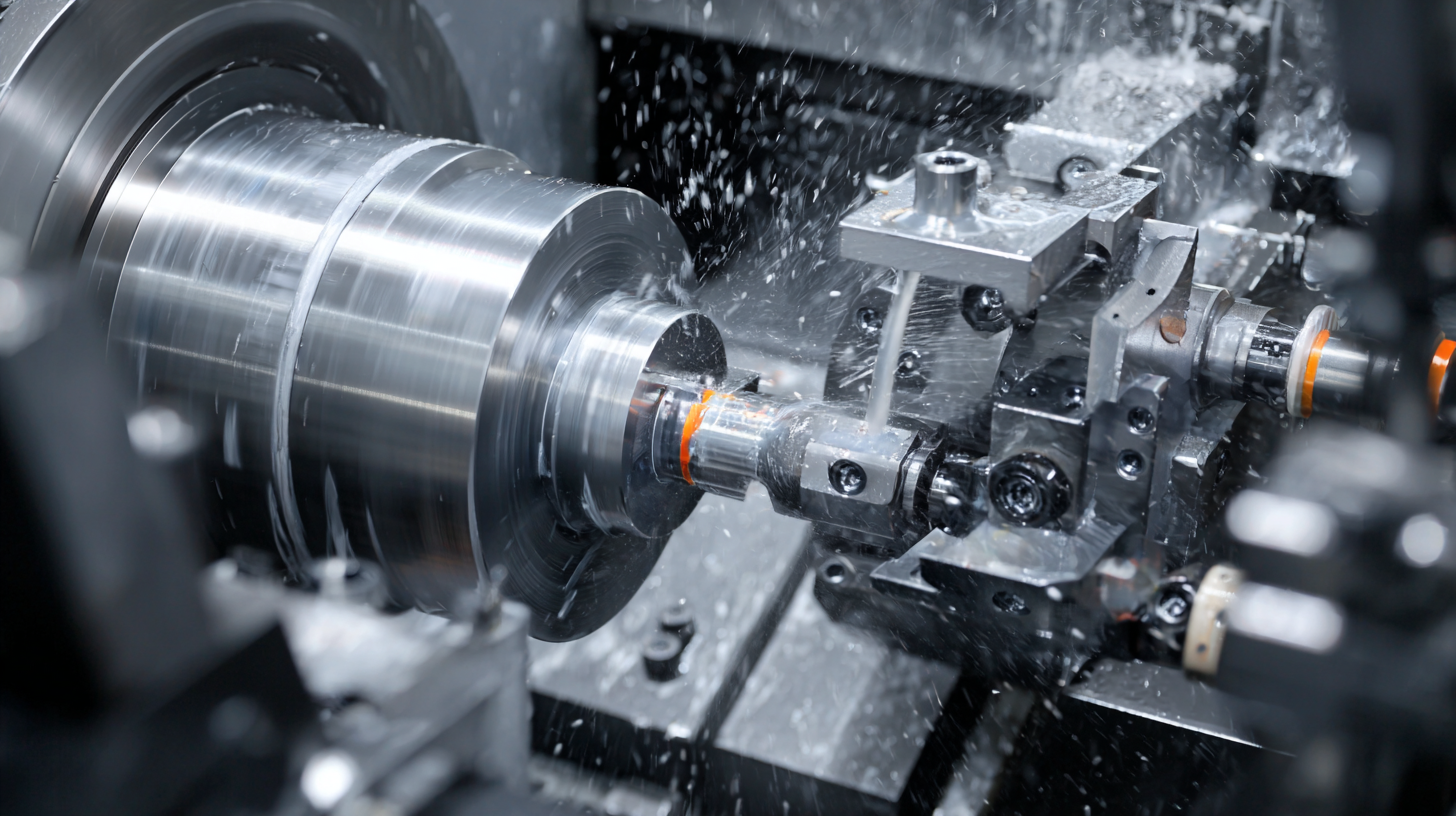

Mill turn machines are becoming increasingly vital in the manufacturing industry, combining the capabilities of milling and turning in a single, efficient setup. Understanding the technology behind these machines can significantly impact a buyer's decision, providing insight into features such as multi-axis operation, automation, and tool interchangeability. These machines leverage advanced CNC technology, allowing for precise machining of complex parts with minimal setup time.

When considering a mill turn machine, it's essential to evaluate the machine's control system. A user-friendly interface and robust software can enhance overall productivity and reduce learning curves for operators. Additionally, investing in machines with adaptive controls can optimize tool paths and machining parameters in real-time, improving efficiency and reducing wear.

Another critical factor is the machine's build quality and rigidity, as these characteristics directly affect its performance and longevity. A strong frame will minimize vibrations during operation, leading to better surface finishes and extended tool life. It's advisable to assess the material composition and craftsmanship of the machine to ensure it meets the demands of your specific applications.

China's Role in the Global Mill Turn Machine Market

China has established itself as a crucial player in the global mill turn machine market, with a robust manufacturing infrastructure and advanced technological capabilities. As demands for precision and efficiency increase in various industries, Chinese manufacturers have invested heavily in researching and developing innovative mill turn machines that cater to diverse applications. This strategic focus not only boosts their domestic market but also positions China as a key exporter, influencing global supply chains.

The country's competitive pricing, coupled with an ever-improving standard of product quality, allows Chinese mill turn machines to appeal to international buyers. Additionally, partnerships between Chinese companies and global firms have led to the exchange of knowledge and technology, enabling better machine performance and functionality. As buyers worldwide seek reliable and high-quality machinery, China's role continues to grow, making it imperative for global buyers to consider Chinese manufacturers in their procurement strategies.

2024 Mill Turn Machines Market Analysis

Comparative Analysis: China vs. Other Leading Manufacturers

In the rapidly evolving landscape of manufacturing, the comparative analysis of mill turn machines from China and other leading manufacturers highlights significant disparities in technological innovation and efficiency. Recent data indicate that China's production capacity has surged, reflecting its status as a key player in the global market. For instance, China has reported a staggering 20% year-on-year growth in CNC machine exports, outpacing competitors in both speed and volume. This aggressive growth is underpinned by substantial government investments and a focus on advanced manufacturing technologies.

However, when examining the innovation characteristics, other manufacturers in regions such as Europe and North America still hold critical advantages in high-precision machining and software integration. For example, European manufacturers leverage superior engineering frameworks, often achieving a 30% higher performance efficiency in benchmark tests. Moreover, a recent comparative study on the leadership dynamics within these companies shows that diversified top management teams significantly influence innovative outcomes, positioning them favorably against their Chinese counterparts, whose centralized decision-making often limits agile responses to market changes. This nuanced landscape underscores the importance of global buyers considering both capacity and innovation when selecting mill turn machines in 2024.

Buying Guide: Essential Considerations for Global Buyers

When considering the purchase of mill turn machines, global buyers must evaluate several critical factors to ensure optimal investment. The market for CNC machining centers is projected to grow from $4.4 billion in 2021 to $6.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.9%. This trend underscores the increasing demand for versatile machines capable of handling complex manufacturing processes. Buyers should prioritize machines that offer superior precision and flexibility, as these traits remain essential in meeting diverse production requirements.

Another consideration is the compatibility of mill turn machines with Industry 4.0 technologies. Many manufacturers are integrating IoT capabilities into their machinery, allowing for real-time monitoring and predictive maintenance. According to a report by MarketsandMarkets, the global IoT in manufacturing market is expected to reach $995 billion by 2025. Buyers should look for models that not only enhance productivity but also fit into the larger digital transformation initiatives, ensuring they remain competitive in a rapidly evolving landscape. The choice of a reliable supplier who can provide training and ongoing support is equally crucial to safeguard long-term operational efficiency.

2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers

| Machine Type | Max Turning Diameter (mm) | Max Machining Length (mm) | Spindle Power (kW) | Control System | Price Range (USD) |

|---|---|---|---|---|---|

| Vertical Mill Turn | 300 | 1000 | 15 | Fanuc | $70,000 - $90,000 |

| Horizontal Mill Turn | 400 | 1500 | 20 | Siemens | $80,000 - $120,000 |

| CNC Mill Turn | 250 | 800 | 10 | Mitsubishi | $60,000 - $85,000 |

| Multi-Tasking Mill Turn | 500 | 2000 | 25 | Heidenhain | $90,000 - $150,000 |