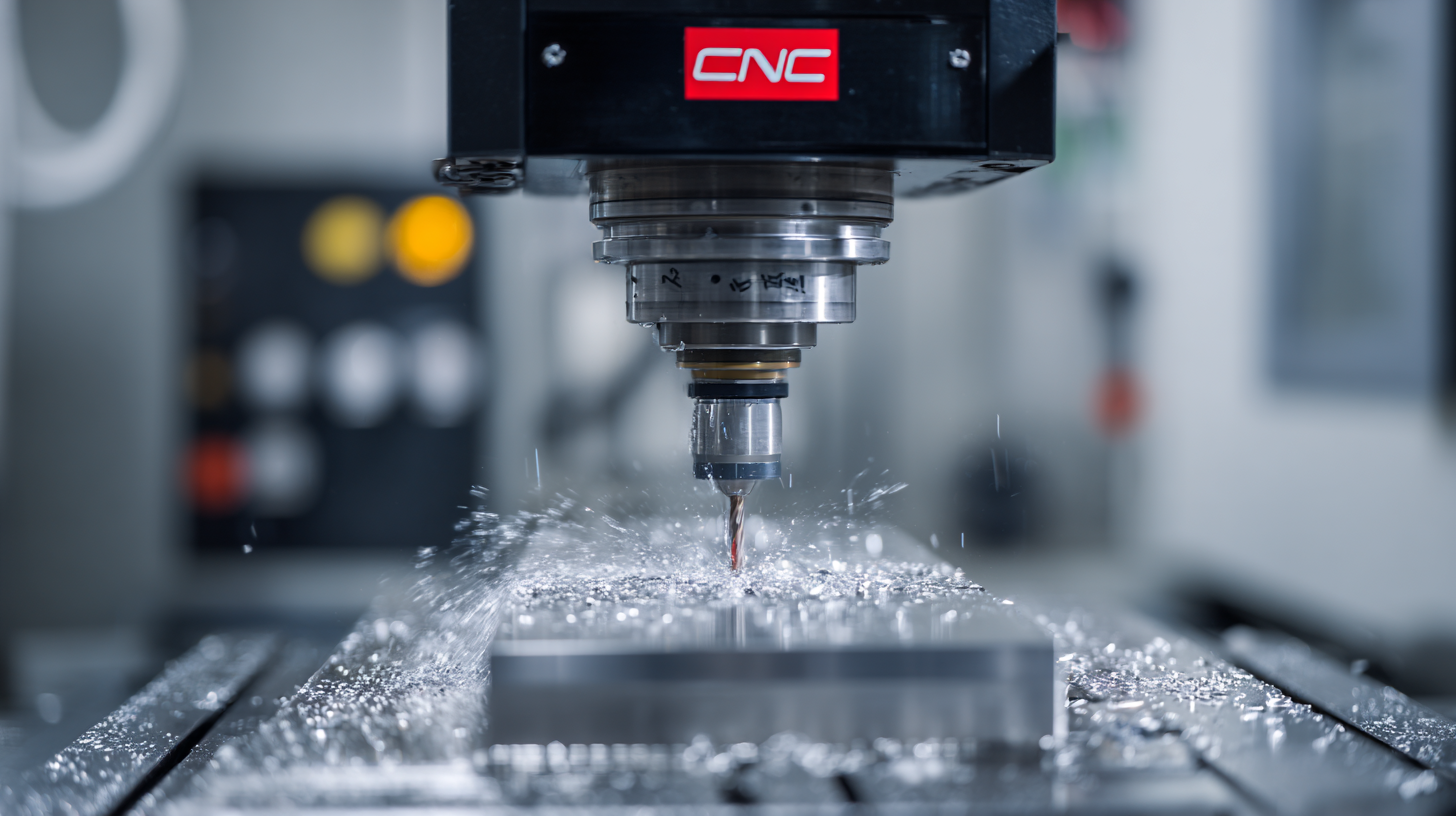

2025 Precision CNC Milling Machine Innovations: Your Ultimate Checklist for Success

In the rapidly evolving world of manufacturing, the precision CNC milling machine stands at the forefront of technological advancements, revolutionizing production processes across various industries. As we look towards 2025, it is essential for businesses to stay ahead of the curve by understanding the latest innovations that these machines bring to the table. This blog serves as your ultimate checklist for success, highlighting the key features, improvements, and essential tips that every operator and engineer should consider when integrating cutting-edge precision CNC milling machines into their workflows. From enhanced automation capabilities to smarter software solutions, the future of milling technology promises not only increased efficiency but also greater versatility, enabling manufacturers to meet the diverse demands of a competitive marketplace. Join us as we explore the crucial aspects that will shape the landscape of precision CNC milling machines in the coming years.

Key Industry Applications of Precision CNC Milling Machines in 2025

In 2025, the landscape of precision CNC milling machines is set to evolve significantly, affecting various key industries. One of the primary applications can be found in the aerospace sector, where high precision and lightweight materials are critical. CNC milling machines will ensure the meticulous fabrication of complex components, such as turbine blades and structural elements, enabling manufacturers to meet stringent safety and performance standards while optimizing fuel efficiency.

Moreover, the automotive industry will harness the power of CNC milling technology to embrace electrification and lightweight designs. As electric vehicles become more prevalent, the demand for precise battery housing and electric motor components will soar. Precision CNC milling machines will play a crucial role in reducing weight while maintaining structural integrity, thereby supporting advancements in sustainable transportation solutions.

Top Innovations in CNC Milling: What to Expect This Year

As we look ahead to 2025, the landscape of CNC milling is poised for remarkable advancements that promise to enhance productivity and precision. One of the most exciting innovations is the integration of AI and machine learning algorithms into CNC systems. These technologies enable real-time data analysis, allowing machines to adapt and optimize milling processes instantly. This not only reduces material waste but also enhances the overall quality of the finished product, making it essential for manufacturers aiming to stay competitive.

Another significant trend is the development of advanced materials and coatings for milling tools. Engineers are experimenting with new alloys and surface treatments that improve tool longevity and resistance to wear and tear. This innovation, coupled with high-speed machining capabilities, will empower businesses to tackle more complex projects with reduced downtime. Additionally, the rise of cloud-based CNC systems will facilitate seamless collaboration and communication between teams, ensuring that operations are synchronized and efficient, regardless of location. These innovations mark a transformative year for the CNC milling industry, paving the way for smarter and more effective manufacturing processes.

How to Select the Right CNC Milling Machine for Your Business

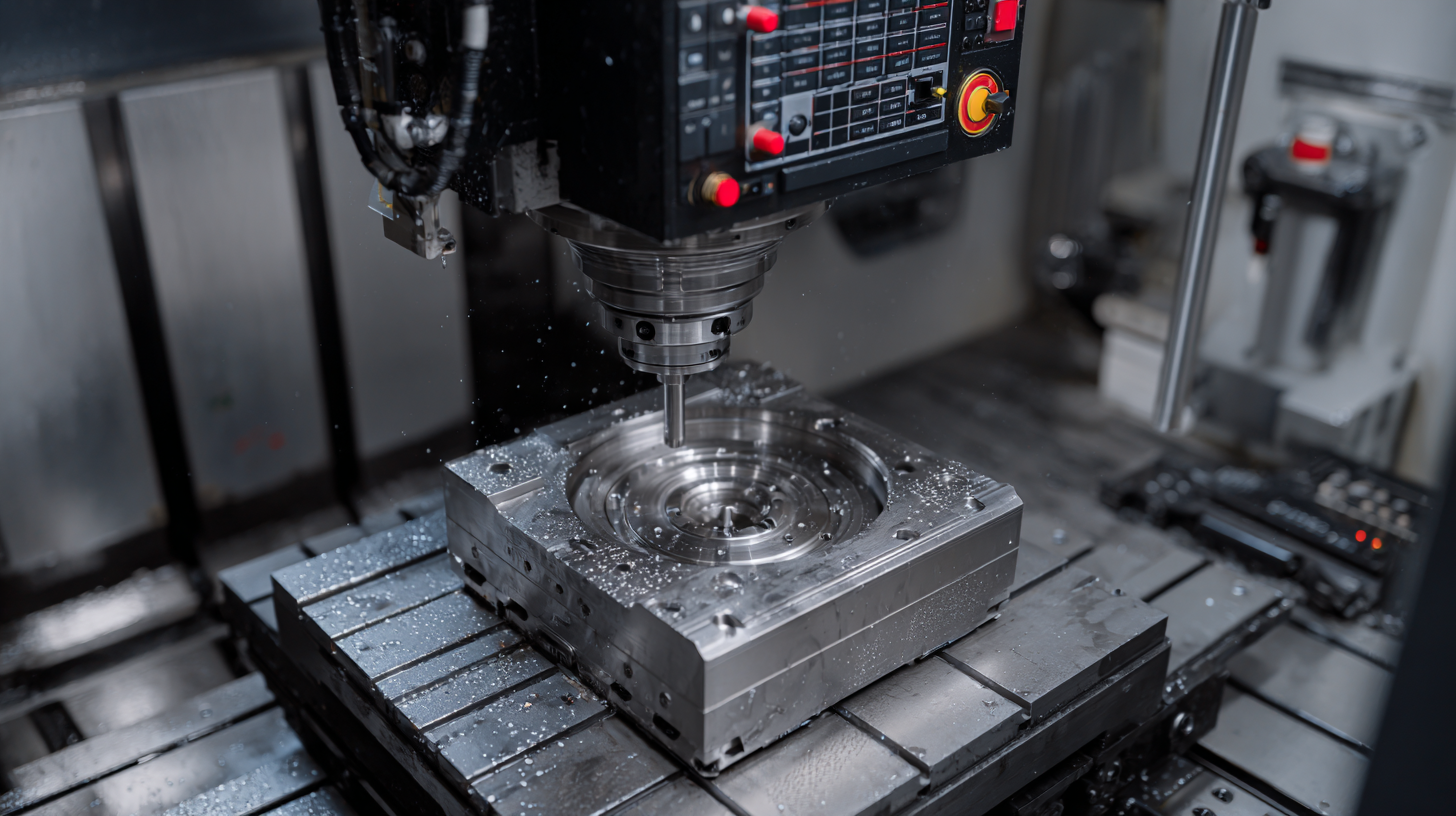

Selecting the right CNC milling machine for your business can significantly impact your production efficiency and product quality. Start by assessing your specific needs, such as the materials you will work with, the complexity of the parts you produce, and your production volume. Understanding these requirements will guide you in choosing a machine that not only fits your budget but also meets the technical demands of your projects.

Tip 1: Consider the type of control system. CNC milling machines come with various control options, including 2D, 3D, and 5-axis capabilities. Assess whether your current or future projects will benefit from advanced control features, as this will help you select a machine that can grow alongside your business.

Tip 2: Evaluate the machine's precision and repeatability. Look for specifications such as the tolerance levels and the type of spindle used. A higher precision CNC milling machine may come at a premium, but the investment can pay off through improved accuracy in machining, reducing material waste, and enhancing overall product quality.

Enhancing Production Efficiency: Best Practices for CNC Milling Operations

In the ever-evolving landscape of CNC milling, adopting best practices is crucial for enhancing production efficiency. First and foremost, regular maintenance of equipment cannot be overlooked. Implementing a scheduled maintenance routine for your CNC milling machines ensures optimal performance and extends the lifespan of the equipment. This not only minimizes downtime but also reduces the risk of costly repairs. Additionally, keeping the machines clean and adequately lubricated can significantly improve precision and machining speed.

Another key aspect is optimizing tool selection and cutting parameters. Choosing the right tools for specific materials and operations can drastically influence the quality of the finished product. Moreover, adjusting feed rates and cutting speeds based on material properties leads to improved chip removal and reduces tool wear. Utilizing advanced monitoring software can assist operators in real-time to make dynamic adjustments, thereby further boosting efficiency on the shop floor. By integrating these practices into CNC milling operations, manufacturers can achieve greater productivity and maintain a competitive edge.

2025 Precision CNC Milling Machine Innovations: Your Ultimate Checklist for Success - Enhancing Production Efficiency: Best Practices for CNC Milling Operations

| Dimension | Description | Best Practices | Efficiency Impact (%) |

|---|---|---|---|

| Machine Calibration | Regular calibration to ensure accuracy | Weekly checks, use precision tools | 15% |

| Tool Selection | Choosing the right tool for the material | Regular reviews of tool performance | 20% |

| Cutting Parameters | Optimizing speeds and feeds | Utilizing software simulations | 25% |

| Maintenance Schedule | Regular machine maintenance | Monthly inspections, quick fixes | 30% |

| Operator Training | Skilled operators for machine handling | Continuous training programs | 40% |

Future Trends in CNC Milling Technology and Their Impact on Industries

As we look toward the future of CNC milling technology, the innovations expected by 2025 promise to transform industries significantly. According to a report by MarketsandMarkets, the global CNC milling machine market is projected to grow from $2.6 billion in 2020 to $4.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10.2%. This growth is driven by advancements in precision and automation, leading to increased efficiency and reduced production costs.

One of the key trends shaping this landscape is the integration of artificial intelligence and machine learning into CNC milling operations. These technologies enable predictive maintenance and real-time monitoring, thus minimizing downtime and enhancing productivity. A recent survey by Research and Markets found that 56% of manufacturers are already investing in smart manufacturing technologies, with a substantial portion focusing on CNC milling innovations. As these systems become more sophisticated, they will allow industries such as aerospace, automotive, and medical devices to achieve higher precision and flexibility, maintaining a competitive edge in an increasingly demanding marketplace.

2025 Precision CNC Milling Machine Innovations: Market Share Forecast

This bar chart shows the projected market share distribution of various CNC milling machine innovations in 2025. The trends indicate a strong preference for 5-axis milling and high-speed milling, while innovations like smart CNC systems are also gaining traction in the market.