Understanding the Benefits of Mill Turn Machines for Efficient Global Manufacturing Strategies

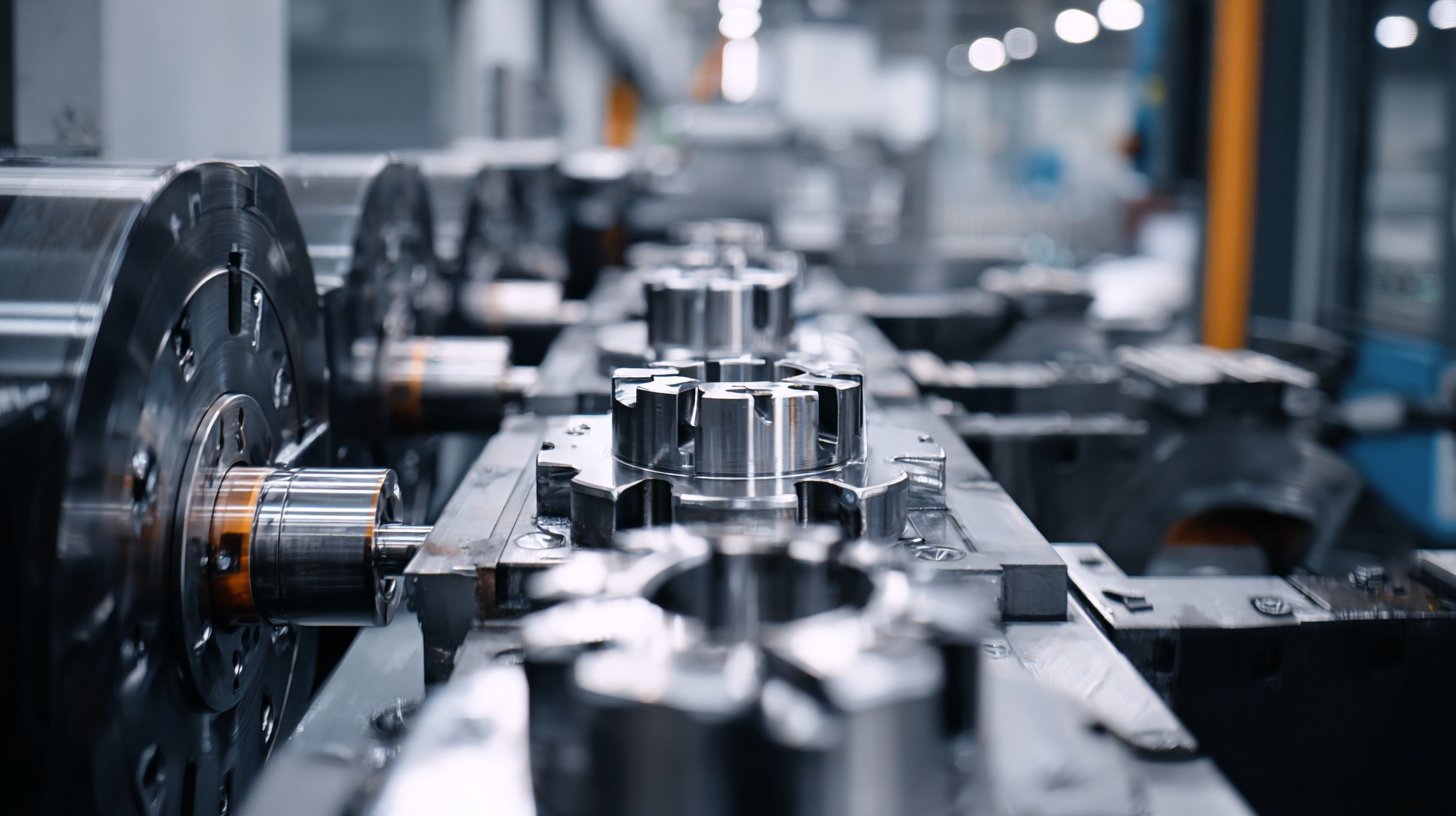

In today’s rapidly evolving manufacturing landscape, the integration of advanced machining technologies has become imperative for achieving operational efficiency and competitiveness. Among these technologies, the mill turn machine stands out as a revolutionary solution, enabling manufacturers to perform multiple machining operations—milling and turning—in a single setup. According to a recent report by Market Research Future, the global CNC machine market is anticipated to grow at a CAGR of 6.5% from 2021 to 2027, driven by the increasing demand for automation in manufacturing processes. The versatility and precision offered by mill turn machines not only reduce cycle times and operational costs but also minimize the risk of errors associated with multiple setups. As companies strive to enhance their global manufacturing strategies, understanding the benefits of incorporating mill turn machines becomes essential for achieving efficiency and maintaining a competitive edge in the market.

Benefits of Mill Turn Machines in Modern Manufacturing Processes

Mill turn machines have revolutionized modern manufacturing processes by integrating both milling and turning capabilities into a single setup. This dual-functionality allows manufacturers to reduce setup times and improve machining accuracy. By minimizing the need for multiple setups and handling, these machines help in streamlining production workflows, leading to significant cost savings and enhanced efficiency.

Moreover, mill turn machines are equipped with advanced technology that enables complex part geometries to be produced with a high degree of precision. This capability is particularly beneficial for industries that require intricate components, such as aerospace and automotive sectors. The ability to perform simultaneous operations on a workpiece means that manufacturers can achieve tighter tolerances and better surface finishes, ultimately meeting the increasing demands for quality in an ever-competitive global market.

Additionally, the versatility of mill turn machines allows for the handling of various materials, making them suitable for diverse applications. From prototyping to high-volume production, these machines adapt to changing manufacturing needs, supporting innovation and flexibility in product design. As companies strive for efficiency in their operations, the adoption of mill turn machines is becoming a crucial element in successful global manufacturing strategies.

Understanding the Benefits of Mill Turn Machines for Efficient Global Manufacturing Strategies - Benefits of Mill Turn Machines in Modern Manufacturing Processes

| Feature | Benefit | Impact on Manufacturing |

|---|---|---|

| Multi-tasking Capability | Reduces number of machines required | Increases operational efficiency |

| Enhanced Precision | Improves product quality | Reduces waste and rework |

| Reduced Setup Times | Minimizes idle time between jobs | Enhances overall production speed |

| Space Efficiency | Requires less floor space | Improves layout and workflow |

| Automation Integration | Supports advanced manufacturing technologies | Increases competitiveness in the market |

| Versatility | Can handle a variety of materials | Expands product offerings |

Key Features of Mill Turn Technology for Enhanced Productivity

Mill turn technology is rapidly transforming the landscape of modern manufacturing, offering manufacturers a unique competitive edge through enhanced productivity. One of the key features of mill turn machines is their capability to perform both milling and turning operations in a single setup. This integration reduces the number of machine setups required, leading to shorter production times and increased efficiency. Furthermore, by minimizing the need for part transfers between different machines, mill turn technology significantly lowers the risk of errors and improves overall product quality.

Another important aspect of mill turn technology is its versatility in handling complex geometries. With advanced CNC capabilities, these machines are capable of executing intricate designs and precision machining with ease. This feature enables manufacturers to produce a wider range of components with varied shapes and sizes, catering to the demands of diverse industries. Additionally, mill turn machines often come equipped with multi-axis capabilities, allowing for dynamic movement and more intricate processing without the necessity for manual adjustments. This not only streamlines operations but also enhances adaptability to changing production needs in a fast-paced global market.

Cost-Efficiency of Mill Turn Machines in Global Manufacturing

Mill turn machines are revolutionizing the landscape of global manufacturing by offering significant cost-efficiency. These advanced machines combine milling and turning operations into a single setup, allowing manufacturers to streamline their processes. By reducing the need for multiple machine setups, companies can save both time and labor costs, leading to a more efficient production cycle. This integration not only minimizes equipment investment but also lessens the human resource burden, translating to direct savings on overhead expenses.

Mill turn machines are revolutionizing the landscape of global manufacturing by offering significant cost-efficiency. These advanced machines combine milling and turning operations into a single setup, allowing manufacturers to streamline their processes. By reducing the need for multiple machine setups, companies can save both time and labor costs, leading to a more efficient production cycle. This integration not only minimizes equipment investment but also lessens the human resource burden, translating to direct savings on overhead expenses.

In addition to the reduction in operational costs, mill turn machines enhance material utilization through precision machining. This efficiency means less waste during the manufacturing process, which is vital in an era where sustainability is paramount. The ability to produce more parts with greater accuracy results in lower costs per unit. As organizations navigate the complexities of a global supply chain, the cost-effectiveness of mill turn machines becomes increasingly appealing, enabling manufacturers to remain competitive while meeting the growing demands of the market.

Integrating Mill Turn Machines into Supply Chain Strategies

Integrating mill turn machines into supply chain strategies offers a transformative opportunity for manufacturers seeking enhanced efficiency and flexibility in today's competitive landscape. With the rise of Industry 4.0, the implementation of advanced technologies such as AI and automated process management is becoming essential. For instance, AI-driven predictive performance tools can streamline operational processes, leading to significant energy savings and reduced waste. This integration aligns well with the industry's broader goals of sustainability, enabling manufacturers to optimize their resources while adhering to eco-friendly practices.

Moreover, by adopting a comprehensive approach that includes integrated tool management software, manufacturers can boost productivity in their tool rooms. This is particularly relevant in sectors like medtech, where precision and reliability are paramount. The ability to manage tools effectively within a digitalized environment enhances a manufacturer's ability to respond to market demands swiftly. As the machine tools market continues to grow, innovations in mill turn technology and process integration will be key drivers in establishing resilient supply chains that can adapt to changing consumer needs while advancing sustainable manufacturing initiatives.

Future Trends in Mill Turn Machinery for Competitive Advantage

Mill turn machines are becoming increasingly vital in the context of future manufacturing trends. As global manufacturing strategies evolve, these machines offer a blend of milling and turning capabilities, allowing for enhanced precision and efficiency. This dual-functionality not only streamlines production processes but also optimizes resource utilization, which is crucial in a competitive landscape. With projections showing significant growth in machinery markets, industries that adopt innovative mill turn technology will likely gain a substantial competitive edge.

**Tips:** When considering the integration of mill turn machines, businesses should evaluate their specific production needs and the types of materials they work with. Additionally, investing in training for operators can enhance the benefits of these machines, ensuring that teams are well-equipped to maximize their capabilities.

As the CNC machine market continues to expand at a compound annual growth rate of 9.9%, leveraging advanced technology like mill turn machines can prove advantageous. Companies focusing on innovation and adaptability can not only improve their manufacturing processes but also respond dynamically to market changes. Incorporating these trends into operational strategies can lead to improved efficiency and increased output, positioning firms favorably for the future.