Top Benefits of Using Precision CNC Milling Machines in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the integration of technology has become paramount. One of the most significant advancements in machining processes is the advent of the precision CNC milling machine. According to industry reports, the global CNC machining market is projected to reach USD 100 billion by 2025, witnessing a CAGR of over 6% from 2020. This growth highlights the increasing adoption of precision CNC milling machines, which offer unparalleled accuracy and efficiency compared to traditional machining tools.

The precision CNC milling machine is renowned for its ability to produce complex geometries with tight tolerances, essential for industries such as aerospace, automotive, and medical devices, where precision is non-negotiable. Research indicates that components manufactured using these machines can achieve tolerances of ±0.005 inches, significantly enhancing product quality and reducing waste. Furthermore, as manufacturers lean towards automation and lean production methodologies, precision CNC milling machines stand out as critical enablers, optimizing production workflows and minimizing human error.

In summary, the transition to precision CNC milling technology not only redefines manufacturing capabilities but also drives economic growth and innovation across various sectors. As the demand for high-precision components continues to surge, investing in precision CNC milling machines is increasingly seen as a strategic advantage in maintaining competitiveness in the global marketplace.

Overview of CNC Milling Machines in Modern Manufacturing

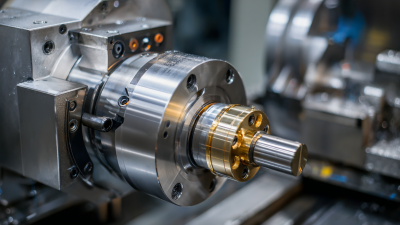

CNC milling machines have revolutionized modern manufacturing by providing precise, efficient, and versatile machining solutions. These machines are controlled by computer numerical control (CNC) systems, allowing for complex designs and high levels of accuracy that were previously unattainable with traditional milling methods. The ability to create intricate components from a wide range of materials has made CNC milling an essential tool in various industries, including aerospace, automotive, and medical device manufacturing.

One of the primary advantages of CNC milling machines is their repeatability. Once a design is programmed into the system, the machine can produce identical parts with minimal deviation, ensuring high-quality output on a consistent basis. This consistency not only enhances product reliability but also streamlines the production process, reducing waste and lowering costs. Additionally, CNC milling machines facilitate rapid prototyping, allowing manufacturers to quickly iterate designs and bring products to market faster than ever before, thus keeping pace with the demands of a fast-evolving landscape.

Key Advantages of Precision CNC Milling Technology

Precision CNC milling technology has revolutionized the manufacturing industry by providing unmatched accuracy and efficiency. One of the key advantages of CNC milling machines is their ability to produce complex geometries with high precision, which is essential for industries requiring tight tolerances. The automation involved in CNC milling reduces human error, ensuring consistent quality across multiple production runs. This level of precision not only enhances product quality but also minimizes material waste, leading to cost savings in the long run.

When utilizing precision CNC milling machines, it's crucial to optimize your setup for maximum efficiency. **Tip:** Always ensure that your tooling is suited for the specific materials you are working with to achieve the best results. Proper maintenance of the machines can also significantly prolong their lifespan and maintain their precision levels.

Additionally, CNC technology allows for rapid prototyping and the ability to easily adjust designs based on feedback. This iterative process accelerates product development and enables manufacturers to stay competitive in fast-paced markets. **Tip:** Regularly reviewing and fine-tuning your CNC programs can help to enhance productivity and reduce cycle times, ultimately driving better profitability.

Top Benefits of Using Precision CNC Milling Machines in Modern Manufacturing

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| High Precision | CNC milling machines achieve high tolerance levels and produce parts that meet stringent specifications. | Enhances quality and reduces waste, leading to higher product quality. |

| Automation | Reduce manual labor through automated processes, allowing for more efficient production. | Increases output and reduces labor costs. |

| Versatility | CNC milling machines can work with various materials, including metals, plastics, and composites. | Allows manufacturers to diversify product offerings. |

| Efficiency | High-speed operations significantly reduce machining time compared to traditional methods. | Shortens lead times, allowing for quicker time-to-market. |

| Repeatability | CNC machines consistently produce the same part with identical specifications. | Reduces variability in manufacturing processes. |

| Complex Designs | CNC technology enables the production of complex geometries that are difficult or impossible to achieve manually. | Enables innovation in product design. |

Enhanced Accuracy and Tolerance in Machining Processes

Precision CNC milling machines play a crucial role in enhancing

accuracy and tolerance in modern

manufacturing processes. According to a report from the International Journal of Advanced Manufacturing Technology, utilizing CNC milling can achieve tolerances as tight as ±0.001 inches in precision machining. This level of accuracy is essential in industries such as

aerospace and

medical device manufacturing, where even the slightest deviation can lead to catastrophic failures or unsafe products.

Furthermore, the integration of advanced CNC milling technologies has led to significant improvements in production efficiency. A study by the National Institute of Standards and Technology (NIST) indicates that the adoption of CNC machining has increased part consistency and reduced the need for manual adjustments, resulting in up to a 30% increase in overall throughput. Enhanced computer control not only streamlines production but also minimizes errors, allowing manufacturers to produce complex geometries with high precision. These advancements underline the critical importance of

CNC milling in maintaining high standards of quality and adaptability in the dynamic landscape of modern manufacturing.

Cost Efficiency and Time Savings in Production

Precision CNC milling machines are revolutionizing modern manufacturing by significantly enhancing cost efficiency and time savings in production processes. These advanced machines operate with remarkable accuracy, allowing manufacturers to produce complex parts and components with minimal waste. This precision reduces the need for excessive material, minimizing costs while ensuring high-quality outputs that meet rigorous industry standards. By employing CNC milling, companies can optimize their production lines, leading to reduced scrap rates and lower overall expenses.

Furthermore, the automation capabilities of CNC milling machines streamline operations, significantly shortening production cycles. With the ability to run multiple machining tasks simultaneously, these machines cut down on downtime and enhance throughput. This means that manufacturers can respond more swiftly to market demands and fluctuations, producing parts at a faster rate without compromising quality. As a result, the integration of precision CNC milling not only drives down operational costs but also positions companies to be more competitive in an ever-evolving market landscape.

Applications and Industries Benefiting from CNC Milling

CNC milling machines have revolutionized various industries by providing high precision and efficiency in manufacturing processes. These advanced machines find applications in sectors such as aerospace, automotive, medical devices, and electronics. For instance, in the aerospace industry, precision CNC milling is crucial for producing intricate components that meet stringent safety specifications and tolerances. Similarly, the automotive sector utilizes CNC milling to fabricate complex parts, ensuring quality and performance in every component produced.

In the medical field, CNC milling machines are instrumental in creating customized implants and surgical instruments, where precision directly impacts patient outcomes. The electronics industry also benefits from CNC technology by producing finely crafted circuit boards and housing for devices. By leveraging the capabilities of CNC milling, manufacturers can enhance product quality, reduce waste, and accelerate production cycles.

Tips: When considering the implementation of CNC milling in your operations, focus on selecting the right materials and understanding the specific capabilities of your equipment. Regular maintenance and training for personnel are also vital to ensure optimal performance and to leverage the full benefits of CNC milling technology. Emphasizing accuracy and efficiency in your manufacturing practices can lead to significant cost savings and improvements in product reliability.

Top Benefits of Using Precision CNC Milling Machines in Modern Manufacturing

This chart illustrates the top benefits of using precision CNC milling machines in modern manufacturing, highlighting their strengths in various areas such as accuracy, efficiency, flexibility, cost reduction, and waste reduction.

Related Posts

-

China's Best Precision CNC Milling Machines Deliver Global Quality You Can Trust

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology

-

Top 7 CNC Lathe and Milling Machines for Precision Engineering in 2023

-

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines