Top 10 Benefits of Using Prototype Machines in Product Development

In the ever-evolving landscape of product development, embracing advanced technologies has become crucial for staying competitive. Prototype machines stand out as essential tools that significantly enhance the efficiency and effectiveness of the design process. As expert Dr. Emily Carter, a leading figure in rapid prototyping, once stated, "Prototype machines not only accelerate the development timeline but also allow designers to iterate on their ideas with unprecedented precision." This underscores the transformative role that these machines play in innovation.

Using prototype machines can streamline workflows, reduce costs, and mitigate the risks associated with product launches. These innovative tools allow engineers and designers to create functional prototypes that resemble the final product, enabling thorough testing and validation before mass production. Ultimately, the integration of prototype machines into product development not only fuels creativity but also ensures that products meet both market demands and quality standards. As we delve into the top ten benefits of utilizing prototype machines, it becomes clear why they are indispensable in modern product development strategies.

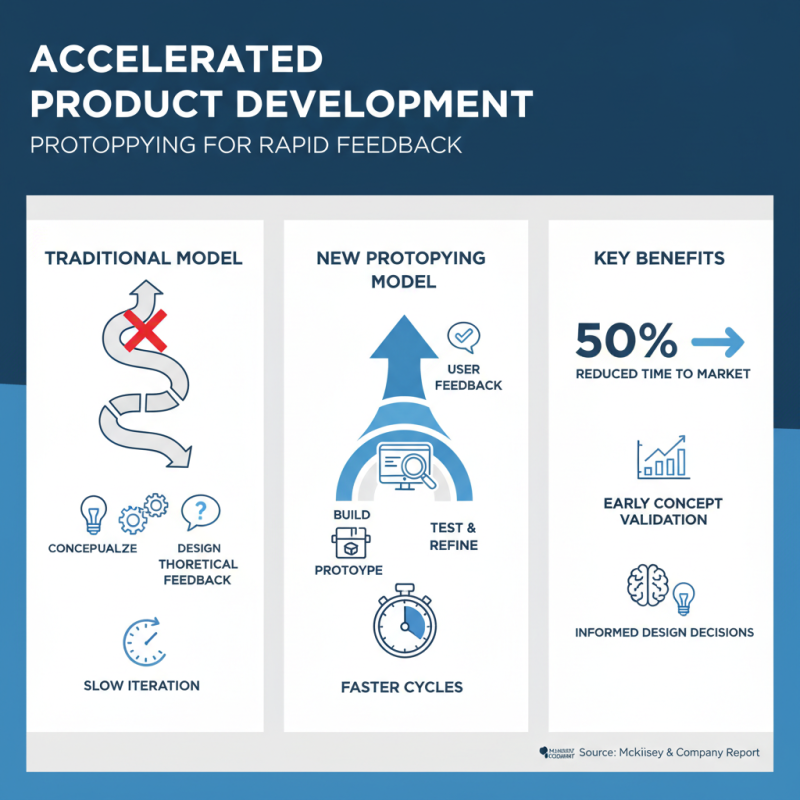

Benefits of Rapid Feedback Loops in Product Development with Prototypes

In today's fast-paced product development landscape, the integration of prototype machines has emerged as a crucial component for achieving rapid feedback loops. According to a recent report by McKinsey & Company, companies that leverage prototyping in their development processes can reduce time to market by up to 50%. This acceleration is primarily due to the ability to test concepts early and iteratively, allowing teams to refine designs based on real user feedback instead of relying solely on theoretical models.

The feedback gathered during prototyping not only informs design decisions but also significantly enhances collaboration among cross-functional teams. A study published in the Journal of Product Innovation Management highlights that organizations embracing rapid prototyping methodologies report a 45% improvement in team productivity. This collaborative environment fosters creative solutions, as diverse perspectives are incorporated into design iterations, ultimately leading to higher quality products that better meet consumer needs. By prioritizing rapid feedback loops through prototyping, businesses can adapt swiftly to market demands, ensuring their offerings remain relevant and competitive.

Enhanced Collaboration Among Development Teams Using Prototype Machines

The integration of prototype machines in product development has transformed how teams collaborate, fostering enhanced communication and creativity. By enabling rapid prototyping, these machines allow team members to visualize concepts in real-time, facilitating immediate feedback and adjustments. This leads to a more iterative design process, where developers, engineers, and designers can work closely together, addressing issues as they arise and refining ideas collaboratively. The hands-on approach taken with prototypes not only makes complex concepts more tangible but also encourages brainstorming sessions to flourish, leading to innovative solutions that might be overlooked in traditional development methods.

Moreover, prototype machines break down barriers between different disciplines within teams. When individuals from various backgrounds work together on tangible prototypes, it promotes a culture of shared understanding and respect for each other’s expertise. This collaboration helps nurture a more dynamic working environment where ideas are exchanged freely, eliminating silos that often stifle creativity. As a result, team members have the opportunity to engage more deeply with each other's perspectives, leading to stronger relationships and a unified vision for the project. By harnessing the capabilities of prototype machines, development teams can maximize their collaborative potential, ultimately driving the success of the product development lifecycle.

Cost-Effectiveness of Early Prototyping in Reducing Project Risks

In the realm of product development, the cost-effectiveness of early prototyping plays a crucial role in mitigating project risks. According to a report by the Product Development and Management Association (PDMA), nearly 60% of product failures can be attributed to inadequate testing and validation during the early stages. Early prototyping enables teams to visualize concepts, identify potential flaws, and make necessary adjustments before committing to full-scale production. By investing in prototype machines, companies can significantly reduce the financial repercussions associated with late-stage changes.

Moreover, McKinsey & Company highlights that incorporating prototyping can save organizations up to 30% in overall project costs. This reduction arises from minimizing rework and avoiding costly errors that might emerge during later phases of development. By leveraging prototype machines, teams are empowered to foster innovation while adhering to tighter budgets and shorter timelines. In sectors like consumer electronics and automotive, where the pace of technological advancement is relentless, the ability to swiftly iterate on designs can directly correlate with market success, enhancing both profitability and competitiveness.

Top 10 Benefits of Using Prototype Machines in Product Development

| Benefit | Description | Cost Reduction (%) | Risk Mitigation (%) | Time Savings (Weeks) |

|---|---|---|---|---|

| Reduced Development Time | Accelerate feedback loops and iterations. | 20% | 40% | 3 |

| Improved Communication | Visual aids enhance collaboration and understanding. | 15% | 30% | 2 |

| Early Problem Detection | Identify issues before production begins. | 25% | 50% | 4 |

| Increased User Feedback | Gather user insights to refine product features. | 10% | 35% | 1 |

| Enhanced Market Readiness | Faster to market with validated concepts. | 30% | 45% | 5 |

| Cost Efficiency | Lower overall project costs through early adjustments. | 20% | 50% | 4 |

| Risk Reduction | Minimize risk associated with product failures. | 35% | 60% | 6 |

| Better Product Quality | Prototype testing improves end product quality. | 15% | 40% | 3 |

| Flexibility in Design | Able to modify designs quickly based on feedback. | 20% | 30% | 2 |

| Competitive Advantage | Faster deployment can give an edge in the market. | 30% | 55% | 5 |

Improved Design Precision Through Iterative Prototyping Processes

Iterative prototyping processes have revolutionized product development by significantly enhancing design precision. By allowing teams to create multiple versions of a product, these processes enable designers to test and refine their concepts based on real-world performance and user feedback. Each prototype serves as a learning opportunity, honing in on details that are often overlooked in initial designs. This continuous cycle of iteration fosters a culture of innovation, ensuring that final products are not only functional but also meet the users' needs more effectively.

Tips for maximizing design precision in your prototyping efforts include involving cross-functional teams early in the process. Collaboration between engineers, designers, and marketing professionals can yield diverse insights that enhance overall product quality. Another crucial tip is to establish clear objectives for each prototype iteration. Define what aspects of the design you want to test or improve, allowing for focused revisions that drive successful outcomes. Additionally, utilizing digital tools for simulations can expedite the prototyping phase, providing immediate feedback and reducing the time taken to reach optimal designs.

Finally, embrace the feedback you gather from testing prototypes with real users. Encourage open and honest evaluations to uncover invaluable perspectives that can refine product functionality and aesthetics. Leveraging these insights not only improves design precision but also strengthens the overall connection between the product and its target audience, ultimately leading to greater success in the market.

Accelerated Time-to-Market for New Products via Prototype Testing

In today's fast-paced market, the ability to bring a product from concept to reality quickly is vital for success. Utilizing prototype machines significantly accelerates time-to-market for new products. By creating tangible prototypes early in the development process, teams can test and refine their ideas in real-world conditions, ensuring that potential issues are identified and addressed before full-scale production begins. This iterative process not only maximizes efficiency but also enhances the quality of the final product.

Tips for effective prototype testing include involving cross-functional teams early in the design phase. Collaborative efforts from various departments such as engineering, marketing, and user experience can yield invaluable insights that improve the prototype's design and functionality. Additionally, prioritize feedback from real users during tests; this can help in making necessary adjustments that align the product with market needs and consumer expectations.

Another key tip is to leverage rapid prototyping techniques, which allow for quick changes based on feedback. Using methods such as 3D printing or CNC machining enables teams to create multiple iterations swiftly, reducing the time spent on each development cycle. This fast-paced approach allows for continuous improvement and adaptation, ensuring that the final product not only meets design specifications but also stands out in the competitive landscape.

Top 10 Benefits of Using Prototype Machines in Product Development

Related Posts

-

Ultimate Guide to Choosing the Best Metal CNC Machine for Your Business

-

Navigating the Future: 2025 Market Insights and How to Choose the Best Basic CNC Machine

-

How to Choose the Best Home CNC Machine for Your DIY Projects

-

2025 Top CNC Metal Milling Machines: Boosting Precision with 98% Efficiency

-

Exploring CNC Milling Machine Innovations at the 2025 China Import and Export Fair

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers