What Makes the Best CNC Aluminium Machine Stand Out in Today's Market?

In today's competitive landscape, the demand for precision and efficiency in manufacturing has never been higher, and the significance of a high-quality CNC aluminium machine cannot be overstated. As industries across the board seek to enhance production capabilities, the ability of a CNC aluminium machine to deliver exceptional results has become a hallmark of success. However, with a multitude of options available, understanding what sets the best machines apart is crucial for making informed purchasing decisions. This blog explores the essential features and innovative alternatives that define the leading CNC aluminium machines in the market today, shedding light on how they meet the diverse needs of engineers, manufacturers, and hobbyists alike. Whether you are looking to invest in your first machine or upgrade your existing setup, recognizing these key differentiators will empower you to select the optimal solution tailored to your specific requirements.

Emerging Trends in CNC Aluminium Machines for 2025: What to Expect

As we look toward 2025, the CNC aluminium machine market is set to evolve with emerging trends that promise to redefine manufacturing efficiency and precision. Recent market research indicates that the global CNC machine tools market is anticipated to experience robust growth, projected to double from USD 97.1 billion in 2024 to USD 196 billion by 2034. This surge reflects a compound annual growth rate (CAGR) of 7.5% from 2025, spotlighting the increasing demand for advanced manufacturing solutions.

In Europe, the CNC machine market is expected to grow at an impressive CAGR of 10.08% from 2025 to 2033, reaching a valuation of USD 52.76 billion. Such rapid growth is indicative of a broader trend towards automation and digitalization in manufacturing, highlighting the crucial role of CNC aluminium machines in optimizing production processes. Furthermore, developments in aluminium extrusion, driven by new energy-related demands, signal a shift in market dynamics. These advancements may lead to the emergence of innovative CNC machining technologies, tailored to meet the evolving needs of industries reliant on aluminium components.

Key Performance Indicators That Distinguish Top CNC Aluminium Machines

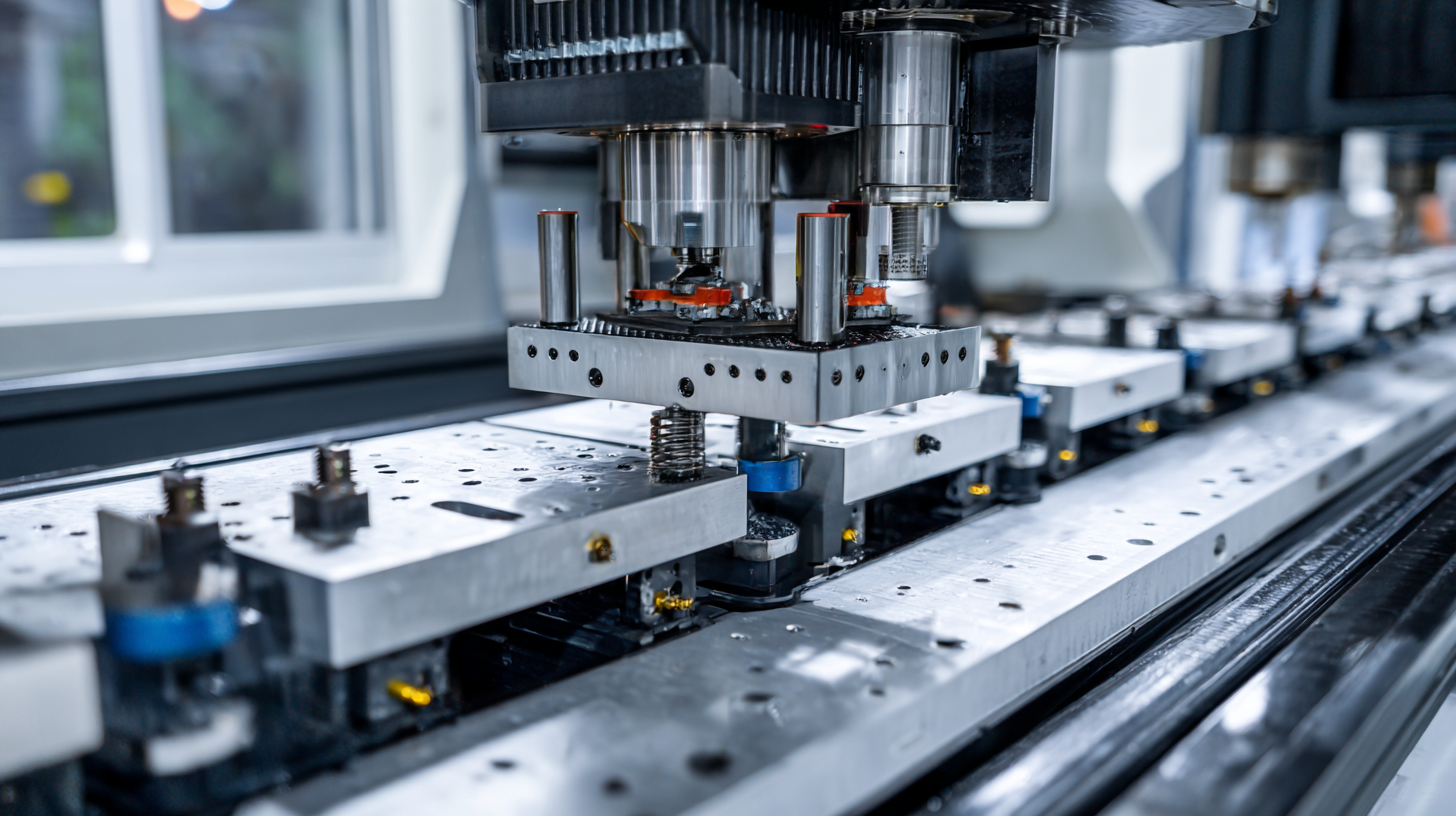

In the competitive landscape of CNC aluminium machines, key performance indicators (KPIs) play a pivotal role in distinguishing the best models from the rest. One essential KPI is the machine's accuracy, which is critical for applications in high-performance sectors like motorsports. Recent advancements have led to billet aluminium engine blocks achieving power levels previously thought impossible, indicating a growing demand for precision machining. According to industry data, machines that offer tighter tolerances and consistent repeatability are increasingly favored, as they directly impact the performance of final products.

Another vital KPI is automation capability. As seen in recent trends, the shift towards automation not only enhances production efficiency but also improves operational reliability. The integration of dual 5-axis machining centers with pallet systems has been identified as a game-changer, allowing manufacturers to streamline workflows and reduce downtime significantly. Reports indicate that businesses leveraging these automated solutions can achieve productivity increases of up to 30%, further solidifying their competitive edge in the market. As the technology landscape evolves, investing in high-performing CNC aluminium machines equipped with advanced KPIs is essential for staying ahead.

Technological Advancements in CNC Machining: Shaping the Future of Aluminium Production

In the rapidly evolving landscape of manufacturing, technological advancements in

CNC machining are redefining

aluminium production. The global CNC machine market is projected to reach $100 billion by 2026, driven largely by innovations such as automation and AI integration.

These technologies enhance precision, reduce error margins, and significantly

increase production speeds, making them indispensable for manufacturers aiming to

meet rising demand.

Incorporating advanced features like live tooling and multi-axis functionality allows

CNC machines to perform complex operations in a single setup, effectively cutting down

on time and costs. Reports suggest that companies adopting these modern CNC solutions

can achieve productivity increases of up to 30%.

Furthermore, advancements in tooling materials and coatings contribute to longer tool life

and lower maintenance costs, providing a compelling return on investment.

Tips: When selecting a

CNC aluminium machine, consider models with adaptive

control capabilities to optimize machining conditions in real-time. Additionally, investing

in training for your operators can maximize the benefits of new technologies, ensuring that your team

is equipped to leverage advancements fully. Finally, keep an eye on software improvements that

integrate seamlessly with your machinery, as these can further streamline production processes.

Market Demand Analysis: How Customer Preferences Influence CNC Machine Design

In today's competitive market, understanding customer preferences is crucial for the design and functionality of CNC aluminium machines. The rising demand for precision engineering and lightweight materials has shaped the way manufacturers approach machine design. Customers are seeking machines that not only deliver high performance but also offer flexibility, efficiency, and ease of use. This trend is reflected in the design innovations that prioritize automation and integration with smart technology, making operations more streamlined and user-friendly.

Additionally, the growth of the grinding machine market underscores the evolving needs of users. The global market for grinding machines was valued at $4.72 billion in 2018, with projections suggesting it could reach $9.01 billion by 2032, growing at a compound annual growth rate of 4.4%. Such statistics highlight the shifting landscape where customer preferences are dictating broader design trends, pushing manufacturers to enhance their offerings. Companies that can adapt to these changing demands, focusing on customization and durability, are more likely to stand out in a crowded marketplace.

Market Demand Analysis of CNC Aluminium Machines

Sustainable Manufacturing Practices: The Role of Eco-Friendly CNC Aluminium Machines

In today's fast-paced manufacturing environment, the demand for eco-friendly practices is more pronounced than ever, particularly in the aluminium machining sector. Eco-friendly CNC aluminium machines play a pivotal role in sustainable manufacturing by optimizing resource use and minimizing waste. These machines are designed to utilize energy-efficient technologies, which consequently lowers the carbon footprint associated with production processes. By integrating advanced machining techniques that require less energy and fewer raw materials, manufacturers can meet increasing eco-conscious consumer demands while still maintaining high productivity levels.

Furthermore, sustainable CNC aluminium machines often incorporate recyclable materials into their designs and processes, reinforcing the commitment to environmental stewardship. By prioritizing the use of biodegradable lubricants and reducing hazardous waste, manufacturers can greatly diminish their ecological impact. This not only benefits the environment but can also enhance the overall reputation of a brand in a market that increasingly values sustainability. Embracing these practices allows companies to position themselves competitively while contributing positively to the planet's health, ultimately defining what makes the best CNC aluminium machines stand out today.