China's Best Precision CNC Milling Machines Deliver Global Quality You Can Trust

In the realm of modern manufacturing, the importance of precision CNC milling machines cannot be overstated. These advanced tools have revolutionized the way components are produced, offering unparalleled accuracy and efficiency. As industries around the globe strive for excellence, China's best precision CNC milling machines stand out for their ability to deliver global quality that can be trusted.

This blog will explore essential tips and insights related to these exceptional machines, highlighting their unique features and applications. Whether you are an industry veteran or just starting your journey in manufacturing, understanding how to select and leverage precision CNC milling machines effectively can significantly enhance production capabilities. Join us as we delve into the world of precision machining, empowering you to make informed decisions that elevate your business operations.

Understanding CNC Milling: A Step-by-Step Guide

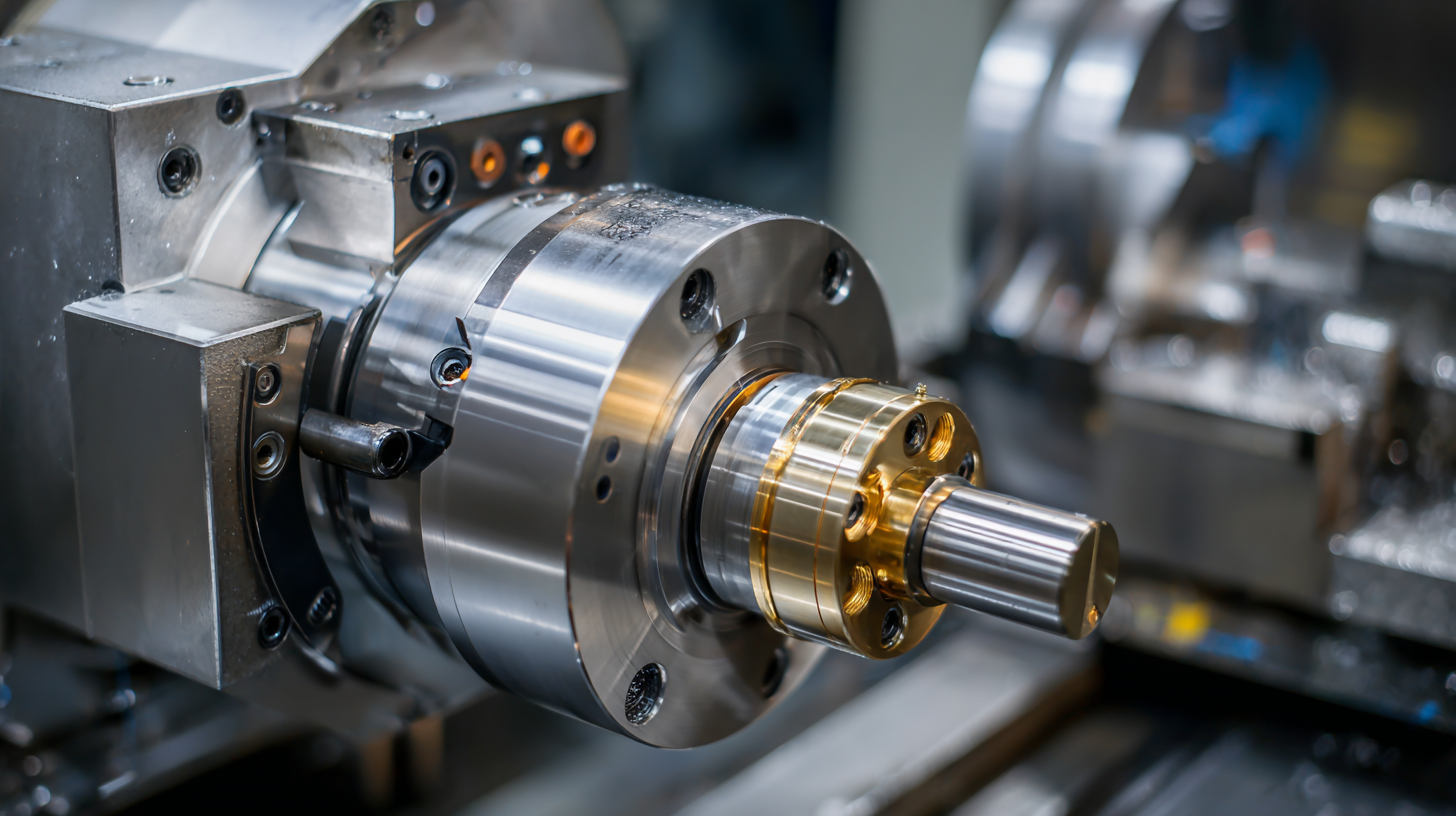

CNC milling is a crucial manufacturing process that employs computer-controlled machinery to create precisely machined parts. The journey begins with a detailed design, often crafted in CAD software, which outlines the specifications and dimensions of the desired component. Once the design is finalized, it is converted into a language the CNC machine can understand, typically via a process called G-code generation. This code directs the machine on how to move, cut, and shape the material, ensuring fidelity to the original design.

The machining process itself involves several key stages, starting with the selection of appropriate raw materials, which could range from metals to plastics. The CNC machine then uses various cutting tools to remove excess material, shaping it into the final product with high accuracy. One of the significant advantages of CNC milling is its ability to produce complex geometries consistently, making it ideal for industries that require precision, such as aerospace and automotive manufacturing. Understanding these foundational steps in CNC milling is essential for anyone looking to appreciate or enter the world of precision engineering.

Key Features of Precision CNC Milling Machines in China

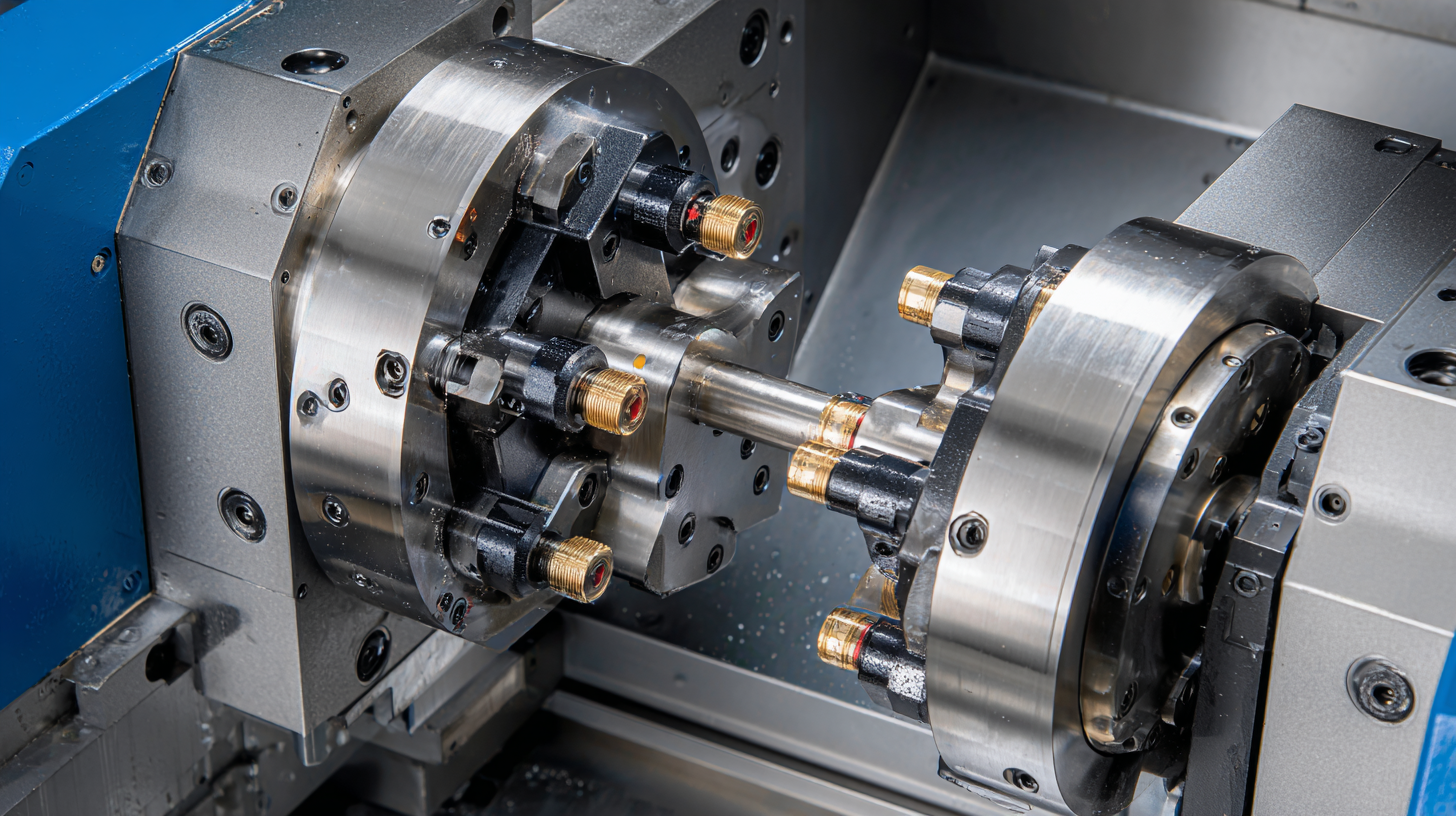

Precision CNC milling machines from China are renowned for their quality and reliability, making them a preferred choice in the global market. Key features of these machines include advanced automation, high-speed operation, and exceptional precision, which allow manufacturers to produce complex parts with minimal error. The integration of innovative technology ensures that these CNC machines can handle a wide variety of materials, including metals and plastics, catering to diverse industrial applications.

Moreover, Chinese manufacturers often emphasize cost-effectiveness without compromising on quality. This balance enables businesses around the world to access cutting-edge CNC milling solutions that are both efficient and budget-friendly. With the global CNC machine market projected to grow significantly, reaching approximately $195.59 billion by 2032, the emphasis on quality and technological advancement in Chinese precision CNC milling machines positions them favorably in a competitive landscape. As industries continue to evolve, these machines will play a critical role in meeting the demands for precision and efficiency in manufacturing processes.

How to Choose the Right CNC Milling Machine for Your Needs

Choosing the right CNC milling machine is crucial for optimizing manufacturing processes and enhancing product quality. With the increasing complexity of components across various industries, selecting a machine that meets specific technical requirements is essential. According to industry reports, the global CNC milling machine market was valued at approximately $1.1 billion in 2020 and is projected to grow at a CAGR of 5.7% through 2027. This growth emphasizes the importance of investing in advanced CNC technology.

When assessing CNC milling machines, consider factors such as precision, speed, versatility, and ease of operation. For instance, machines with higher spindle speeds can significantly reduce machining time, thus increasing overall productivity. It’s also important to look for machines equipped with sophisticated software that can handle complex geometries and provide real-time feedback to operators.

**Tips:** Always evaluate the machine's specifications against the materials you’ll be working with. If you need to work with hard metals, ensure the spindle power and torque are sufficient. Furthermore, consider the after-sales service and availability of spare parts, as these can greatly affect your maintenance costs and operational uptime. Investing time in selecting the right machine can lead to enhanced efficiency and quality in your manufacturing processes.

Maintenance Tips for Maximizing CNC Milling Machine Performance

Maximizing the performance of CNC milling machines is essential for manufacturers aiming to enhance efficiency and productivity. As the

CNC machine market is projected to grow significantly, from

$101.22 billion in 2025 to

$195.59 billion by 2032 at a

CAGR of 9.9%, it becomes increasingly important to implement effective maintenance strategies.

Regular maintenance not only prevents downtime but also extends the lifecycle of these precision machines.

One effective approach to maintenance involves utilizing predictive analytics and

machine learning techniques, which can forecast potential issues before they escalate.

By analyzing operational data, manufacturers can identify patterns and anomalies that may indicate machine wear or failure. For example, advanced

research has shown that leveraging three-axis vibration data can be instrumental in diagnosing faults in CNC hobbing cutters, leading to

timely interventions and reduced repair costs.

Furthermore, comprehensive maintenance routines should incorporate

routine inspections, lubrication, and calibration to ensure optimal machine

performance. As CNC milling machines become more automated and intelligent, staying on top of maintenance will allow manufacturers to fully

leverage the capabilities of their equipment, minimizing the trial-and-error processes often associated with machining.

Comparing Global Quality Standards for CNC Milling Machines

When it comes to CNC milling machines, quality is a critical factor that determines their efficacy and reliability in manufacturing. The global market has set various quality standards that manufacturers must adhere to, ensuring that precision tools can deliver impeccable results. Notably, China's CNC milling machines have been recognized for meeting and often exceeding these standards, showcasing their commitment to excellence and precision engineering.

A comparison of global quality standards reveals that while many countries have established rigorous benchmarks, China's approach integrates advanced technology with traditional craftsmanship. This blend not only enhances the machine's capability but also positions Chinese manufacturers as competitive players on the world stage. By focusing on fine-tuning production processes and incorporating state-of-the-art technology, these mills deliver the robustness and accuracy that industries around the globe rely on. As manufacturers seek machines that ensure high performance and low downtime, China's precision CNC milling machines emerge as a trusted choice, embodying global quality you can depend on.