How to Choose the Best Home CNC Machine for Your DIY Projects

When embarking on DIY projects, selecting the right tools is crucial for achieving professional results, and this is where a home CNC machine comes into play. These versatile devices empower hobbyists and professionals alike to transform their creative ideas into tangible products with precision and ease. However, with a myriad of options available on the market, choosing the best home CNC machine can be a daunting task. This guide aims to simplify that process by highlighting key features to consider, evaluating different types of machines, and offering insights on how to align your specific project needs with the right CNC technology. Whether you’re looking to craft intricate designs, cut materials, or engrave custom items, understanding the essential components and capabilities of home CNC machines will help you make an informed decision and elevate your DIY endeavors.

When embarking on DIY projects, selecting the right tools is crucial for achieving professional results, and this is where a home CNC machine comes into play. These versatile devices empower hobbyists and professionals alike to transform their creative ideas into tangible products with precision and ease. However, with a myriad of options available on the market, choosing the best home CNC machine can be a daunting task. This guide aims to simplify that process by highlighting key features to consider, evaluating different types of machines, and offering insights on how to align your specific project needs with the right CNC technology. Whether you’re looking to craft intricate designs, cut materials, or engrave custom items, understanding the essential components and capabilities of home CNC machines will help you make an informed decision and elevate your DIY endeavors.

Factors to Consider When Selecting a Home CNC Machine for DIY Projects

When selecting the best home CNC machine for your DIY projects, several factors play a crucial role in ensuring that you get the most suitable model for your needs. First, consider the machine's material compatibility. Depending on whether you plan to work with wood, metal, or plastics, you'll need a CNC machine that can handle those specific materials effectively. Make sure to check the machine's specifications and capabilities to ensure it matches your project requirements.

Tips: Look for machines with a versatile range of tooling options to accommodate various materials. This flexibility will allow you to experiment with different projects without the need for multiple machines.

Another important factor is the size and working area of the CNC machine. Assess your workspace and the dimensions of the projects you envision. A compact CNC machine may be ideal for smaller projects, while a larger model will be necessary for bigger undertakings. Additionally, think about the machine's ease of use—user-friendly software and intuitive controls can significantly enhance your DIY experience.

Tips: Prioritize machines with good customer support and active communities online. This can provide you with valuable resources and troubleshooting tips as you navigate your CNC journey.

Types of CNC Machines: Which One Suits Your DIY Needs?

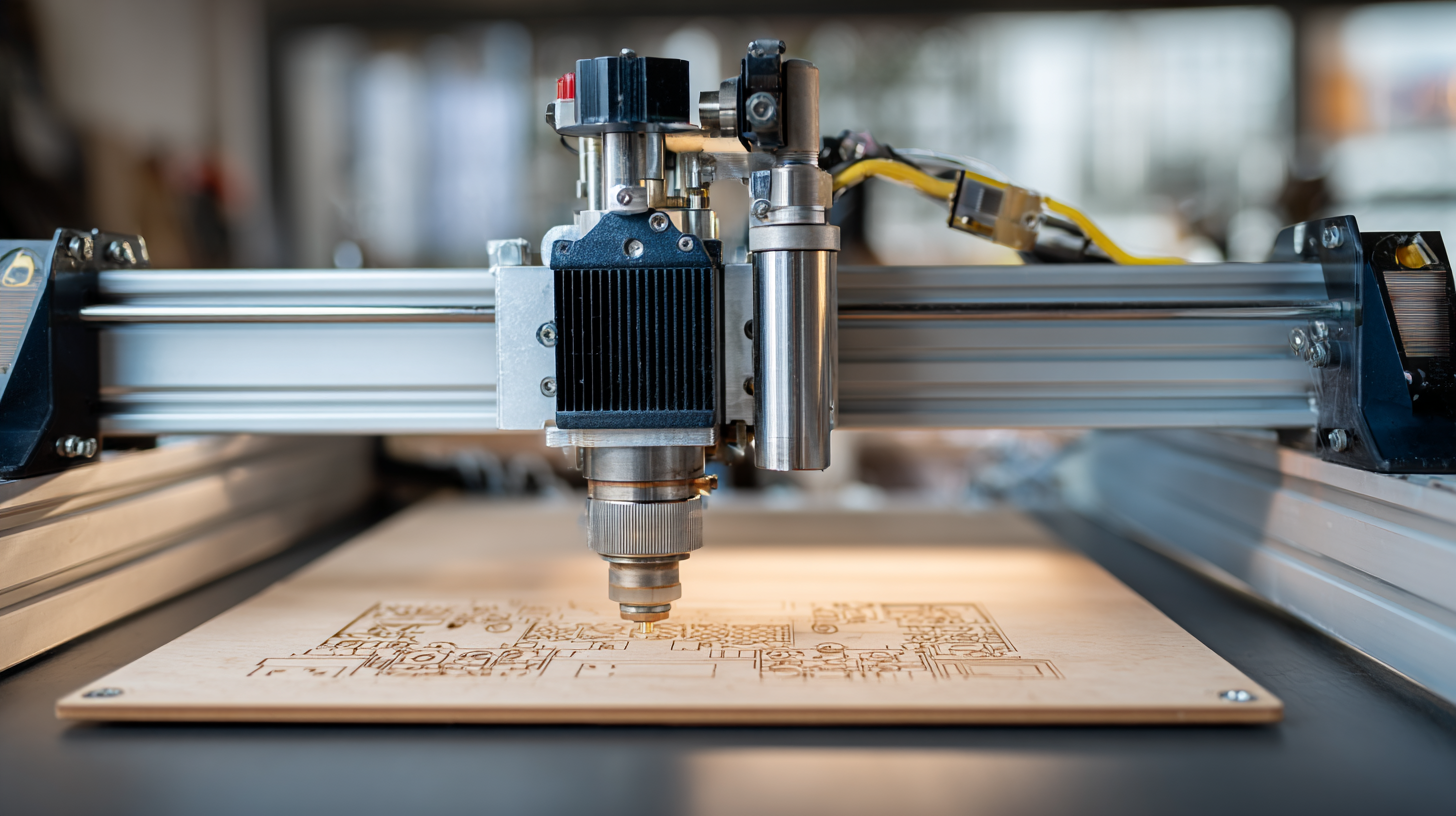

When selecting a CNC machine for your DIY projects, it’s crucial to understand the various types available, each tailored for specific needs. A popular choice is the CNC router, which excels at cutting, carving, and engraving on materials like wood, plastic, and soft metals. This versatility makes it ideal for woodworking projects, DIY furniture, and intricate designs. If you're focused on metalworking, a CNC milling machine might be more suitable, as it can tackle harder materials with precision, allowing for the production of complex parts and prototypes.

For those interested in 3D printing, a CNC 3D printer offers the ability to fabricate three-dimensional objects from digital files. This type of machine is perfect for creating models, prototypes, and custom designs, particularly in home décor or small-scale manufacturing. Additionally, laser engravers serve a unique niche by offering detailed engraving and cutting capabilities, especially for materials like acrylic, leather, and even glass. Ultimately, the choice of CNC machine depends on the specific applications and materials you plan to work with, ensuring that you select the right tool for your creative projects.

Popular Types of CNC Machines for DIY Projects

Budgeting for Your Home CNC Machine: Finding the Right Balance

When budgeting for a home CNC machine, it's essential to strike the right balance between cost and functionality. The initial investment can vary significantly depending on the machine's capabilities, from basic models suitable for hobbyists to advanced systems designed for professionals. Start by clearly defining your project needs; whether you need a machine for engraving, milling, or 3D printing will determine the features you require and, subsequently, the budget.

It's also crucial to consider the long-term costs associated with your CNC machine. This includes maintenance, software, and additional accessories like bits and tools. While it may be tempting to opt for the cheapest option available, investing in a higher-quality machine can yield better performance and durability, ultimately saving money over time. Additionally, look for machines with good customer support and a robust online community, as these resources can prove invaluable in troubleshooting and enhancing your DIY experience. Balancing your budget while ensuring the capabilities you need will lead to more successful and enjoyable projects.

How to Choose the Best Home CNC Machine for Your DIY Projects

| Feature | Description | Price Range | Ideal For |

|---|---|---|---|

| Workspace Size | Consider the size of the projects you want to create. | $500 - $3000 | Small to Medium Projects |

| Material Compatibility | Check which materials can be used, such as wood, plastic, and metals. | $600 - $4000 | Mixed Material Projects |

| Ease of Use | User interface and software must be user-friendly. | $400 - $2500 | Beginners |

| Speed and Precision | Important for detailed and intricate designs. | $700 - $5000 | Professional Projects |

| Support and Community | Availability of tutorials, forums, and customer support. | Varies | All Users |

Key Features to Look for in a DIY CNC Machine

When selecting a home CNC machine for your DIY projects, it's crucial to focus on key features that will enhance both the usability and versatility of the device.

Consider the machine's build size; larger machines can handle bigger projects, while compact models fit well in limited spaces. Additionally, investigate the types of materials the CNC can work with, such as wood, plastic, and metals. A machine that supports a variety of materials expands your project possibilities significantly.

Consider the machine's build size; larger machines can handle bigger projects, while compact models fit well in limited spaces. Additionally, investigate the types of materials the CNC can work with, such as wood, plastic, and metals. A machine that supports a variety of materials expands your project possibilities significantly.

Tips: Ensure the CNC machine has a robust software package that offers user-friendly interfaces and sufficient design capabilities. The ease of software operation can drastically affect your workflow efficiency. Also, check for online support and community resources that can assist you with troubleshooting and project ideas.

Moreover, pay attention to the precision and accuracy ratings of the machine, as these factors are essential for achieving professional-quality results in your DIY projects. A machine with high precision will reduce material waste and save time during the setup and execution of intricate designs. Look for models that have received positive reviews for their reliability and performance, as user experiences often provide valuable insights.

Tips for Setting Up Your CNC Machine for Optimal Performance

When setting up your CNC machine for optimal performance, one of the first things to consider is the environment in which it will operate. Ensure that the workspace is well-ventilated, free from dust, and maintains a stable temperature. Proper insulation can also help in minimizing vibrations that might affect the precision of your cuts. Additionally, having a solid, level surface for your machine is crucial to prevent wobbling during operation, which could lead to inaccuracies in your projects.

Another vital aspect to focus on is the software configuration. Choose user-friendly CNC software that suits your skill level and project needs. Spend time learning how to use the software effectively, as a good understanding of the programming will lead to better outcomes. It’s also essential to keep the machine's firmware updated, which can enhance performance and introduce new features that improve operational efficiency. Regular maintenance, including lubrication and inspection of cutting tools, will further ensure that your CNC machine runs smoothly and lasts longer.

Related Posts

-

Unlocking Innovation with the Best CNC Machine Milling Machine Options for Global Buyers

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

The Future of Innovative Aluminium Milling Machines in Global Manufacturing

-

What is the Best CNC Turning Machine for Your Manufacturing Needs?

-

Unlocking Your CNC Aluminium Machine Potential 5 Essential Tips for Global Buyers

-

10 Digital Tips for Choosing the Perfect Micro CNC Milling Machine for Your Business Needs