How to Choose the Best Micro CNC Milling Machine for Your Needs

In recent years, the demand for micro CNC milling machines has surged, driven by the expanding applications in sectors such as electronics, aerospace, and medical device manufacturing. According to a report by ResearchAndMarkets, the global CNC machine market is projected to reach $100 billion by 2026, with micro CNC milling machines representing a significant segment due to their ability to produce intricate components with precision and efficiency.

As industries increasingly lean towards automation and precision engineering, selecting the right micro CNC milling machine tailored to specific needs becomes critical. This blog will explore essential factors and criteria to consider, helping you navigate the myriad of options available in the market and ensure that your investment aligns perfectly with your operational requirements.

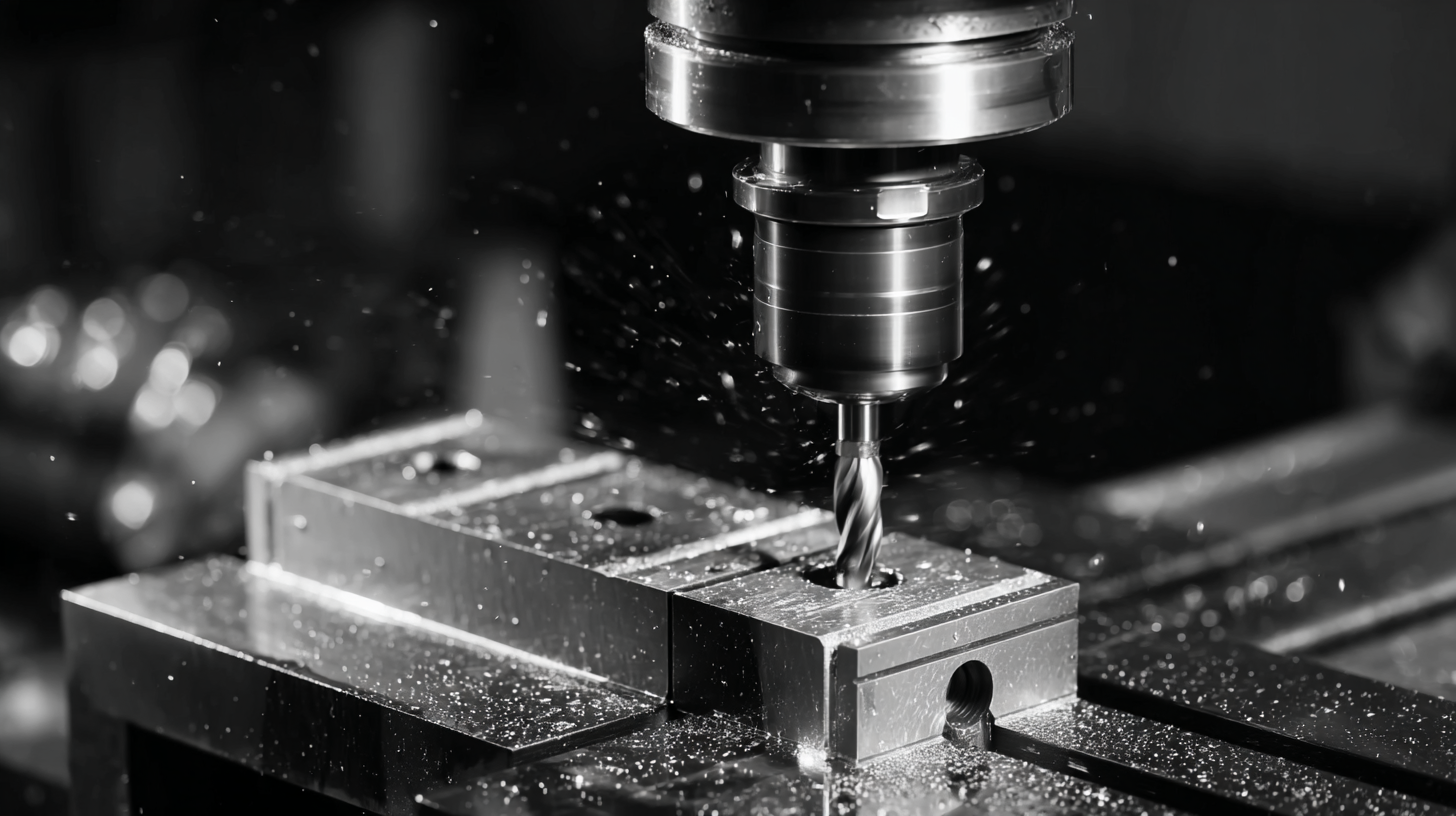

Understanding Micro CNC Milling Machines: Key Features and Specifications

When selecting a micro CNC milling machine, understanding its key features and specifications is essential for making an informed decision. Start by examining the machine's precision and repeatability, as these factors directly impact the quality of your finished products. A unit with a high resolution of at least 0.001 inches will ensure that even the most intricate designs are accurately reproduced. Additionally, consider the type of materials you plan to work with; different machines have varying capabilities regarding material hardness and thickness.

Another critical specification to evaluate is the spindle speed and power. A high-speed spindle allows for faster cutting, which can significantly enhance productivity. For versatility, look for machines that offer adjustable speeds and additional tooling options. Remember that the machine's bed size will also affect the dimensions of the parts you can create; therefore, ensure that it aligns with your project needs.

Tips: Pay attention to customer reviews and manufacturer warranties to gauge reliability. Always verify the availability of technical support and replacement parts, as this can save you significant time and trouble in case of breakdowns. Don't hesitate to ask the seller about demo units or trials, as hands-on experience can provide valuable insights into the machine's operation.

Market Trends: Projected Growth of Micro CNC Milling Machines by 2025

As we look ahead to 2025, the market for micro CNC milling machines is poised for significant growth. The increasing demand for precision engineering in various industries, including Aerospace, Automotive, and Medical Devices, underscores the importance of these compact machines. Factors such as technological advancements and the proliferation of small-scale manufacturing are driving this surge. By investing in a micro CNC milling machine, businesses can enhance their production capabilities, meet stringent quality standards, and reduce overall operating costs.

When choosing the best micro CNC milling machine for your needs, consider the following tips:

- Evaluate the machine's specifications: such as spindle speed, accuracy, and size, to ensure it meets your project requirements.

- Assess the availability of support and training: from the manufacturer, as well as the community resources like forums and tutorials, which can be invaluable in maximizing your machine's potential.

- Customer reviews and case studies: are vital; they provide insights into real-world performance and reliability, helping you make a more informed decision.

Assessing Your Needs: Choosing the Right Size and Functionality for Your Projects

When choosing a micro CNC milling machine, understanding your specific needs is crucial. The size of the machine is a primary consideration, as it directly affects the scope of your projects. According to a report by Research and Markets, the global CNC machine market is expected to grow at a CAGR of 6% from 2021 to 2026, highlighting the increasing demand for precision machinery across various industries. Selecting a compact option can be advantageous for hobbyists or small businesses operating in limited spaces, while those engaged in larger-scale manufacturing might require a more robust system.

Functionality is another key factor. Various CNC milling machines offer distinct capabilities, from simple engraving tasks to complex part machining. A report by Technavio predicts that the CNC milling machine market will witness a rise in demand for machines with advanced features such as automation and multi-axis capabilities, which enhance productivity and precision. Assessing the materials you plan to work with, the dimensions of parts needed, and your budget will inform your choice and ensure you invest in a machine that meets your project requirements effectively. Balancing these aspects will lead you to a machine that not only fits your workspace but also aligns with your project goals.

Comparative Analysis: Leading Brands and Models in the Micro CNC Milling Market

When selecting the best micro CNC milling machine, it's essential to conduct a comparative analysis of leading brands and models in the market. Renowned brands like Tormach, Shapeoko, and Stepcraft offer unique features tailored for various needs, from hobbyists to professional machinists. For instance, Tormach's machines are known for their robust design and versatility, making them suitable for both complex and simple machining tasks. Shapeoko, on the other hand, excels in affordability and ease of use, appealing to those new to CNC milling.

Tips for choosing the right micro CNC milling machine include assessing the machine's build quality and precision capabilities. Look for machines constructed with durable materials that provide stability during operation. Additionally, review the available tooling options and software compatibility, as these factors significantly affect your machining efficiency and product quality.

Finally, consider your specific project requirements, such as the size of your workspace and the types of materials you'll be working with. Some models are designed for smaller projects, while others offer more extensive capabilities. By thoroughly comparing features and understanding your needs, you can make an informed decision that aligns with your CNC milling goals.

Cost Considerations: Budgeting for Your Micro CNC Milling Machine Purchase

When considering the purchase of a micro CNC milling machine, budgeting is crucial to ensure you can meet both your operational needs and financial constraints. Current market trends reveal that while entry-level micro CNC machines can be found for as low as $300, higher-end models equipped with advanced features can range from $1,000 to $3,000 or more. A report from the CNC Machine Tool Market indicates a projected growth rate of 6.5% annually, underscoring increasing demand and innovation in this sector, making it essential to carefully assess your specific requirements.

Cost considerations extend beyond the initial purchase price; maintenance, tooling, and materials can contribute significantly to your total expenditure. For example, if you plan to mill aluminum, you may need specialized tooling that can drive up your costs, with quality bits averaging around $20 each. Additionally, a recent analysis of desktop CNC machines emphasized the importance of versatility, as many hobbyists are now looking for machines that can handle multiple materials beyond just wood or plastic. This evolution in user needs highlights the importance of investing in a model that not only fits within your budget but also provides the flexibility to grow with your projects.

How to Choose the Best Micro CNC Milling Machine for Your Needs - Cost Considerations: Budgeting for Your Micro CNC Milling Machine Purchase

| Feature | Entry-Level ($1000 - $3000) | Mid-Range ($3000 - $6000) | High-End ($6000+) |

|---|---|---|---|

| Build Quality | Basic materials, limited precision. | Moderate build quality, good precision. | High-quality materials, excellent precision. |

| Spindle Power | Low power, suitable for soft materials. | Moderate power, can handle metals and harder materials. | High power, designed for diverse and tough materials. |

| Software Compatibility | Basic software included, minimal features. | Compatible with multiple CAM software. | Advanced software options and features included. |

| Customer Support | Limited support, mainly online resources. | Good customer support, resources available. | Excellent support, dedicated service teams. |

| Warranty Period | 1 year warranty. | 2 year warranty. | 3 year warranty or more. |