Top Strategies for Maximizing Efficiency with the Best Home Shop CNC Machine

In today's rapidly evolving manufacturing landscape, the significance of the home shop CNC machine has escalated, particularly in promoting productivity and precision for both hobbyists and professionals alike. According to a report by Smith Nano Technologies, the global CNC machine market is expected to reach $100 billion by 2026, underscoring the growing demand for user-friendly solutions that fit smaller operations.

With advancements in technology, modern home shop CNC machines offer features like improved automation and integration capabilities, ensuring that even amateur craftsmen can achieve professional-quality results. Notably, the trend of "Made in China" has transformed this sector, with Chinese manufacturers leading the charge in quality and affordability. This blog will explore top strategies that can help users maximize efficiency while leveraging the best home shop CNC machines, ensuring they remain competitive in today's market.

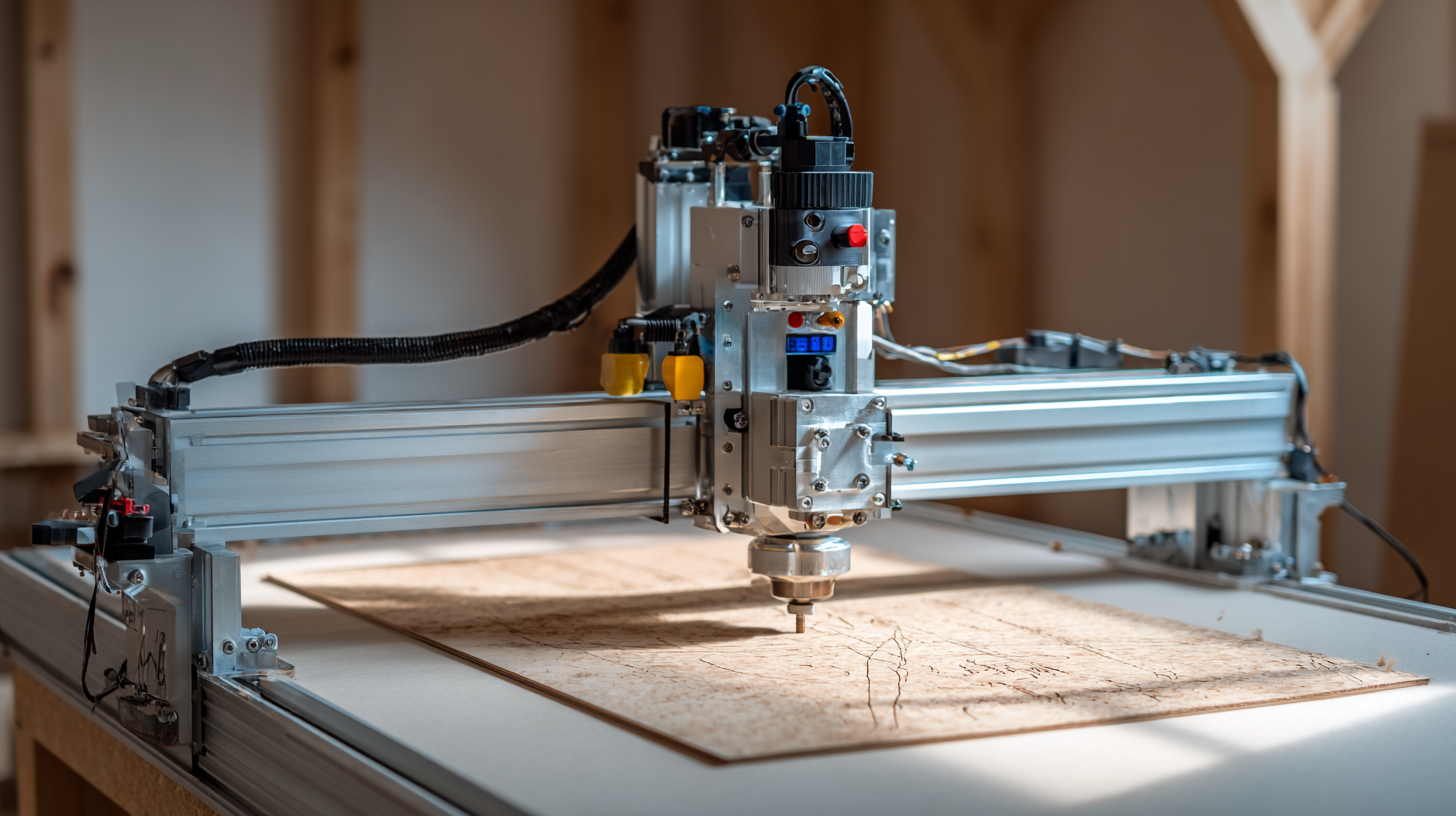

Understanding the Basics of CNC Machines for Home Workshops

CNC machines have revolutionized home workshops by providing a level of precision and automation that hand tools simply cannot match. Understanding the basics of CNC technology is crucial for anyone looking to maximize their efficiency in a home shop environment. At its core, a CNC (Computer Numerical Control) machine utilizes computer software to control the movement of tools and machinery, allowing for intricate designs and consistent results with minimal manual intervention. This functionality makes CNC machines indispensable for tasks ranging from woodworking to metalworking, enabling hobbyists and professionals alike to elevate their craftsmanship.

To get started with a CNC machine in your home shop, it's essential to familiarize yourself with key components such as the controller, spindle, and tool selection. The controller is the brain of the operation, translating design files into precise movements. Understanding how to generate and manipulate G-code—the language in which CNC machines operate—is equally important, as it dictates the movements and actions of the machine. Moreover, choosing the right tools based on the materials you'll be working with can significantly influence your project's outcome. With a solid grasp of these fundamentals, you can leverage the full potential of your CNC machine to create complex and high-quality workpieces efficiently.

Top Strategies for Maximizing Efficiency with the Best Home Shop CNC Machine

| Feature | Description | Efficiency Impact | Recommended Usage |

|---|---|---|---|

| CNC Controller | Software that processes G-code and controls CNC operations. | High; enables precise operations and reduces errors. | Ideal for intricate designs and repetitive tasks. |

| Material Compatibility | Ability to work with various materials such as wood, plastic, and metal. | Moderate; expands project possibilities but requires specific settings. | Versatile projects across different materials. |

| Cutting Speed | Speed of the cutting tool during operation. | High; can significantly reduce production time if adjusted properly. | Good for bulk production tasks. |

| Tool Changes | Efficiency of changing tools during a job. | High; automated tool changers save time. | Complex projects with multiple tool requirements. |

| User-Friendly Interface | Ease of use of the software and controls. | High; reduces learning curve and increases productivity. | Suitable for beginners and professionals alike. |

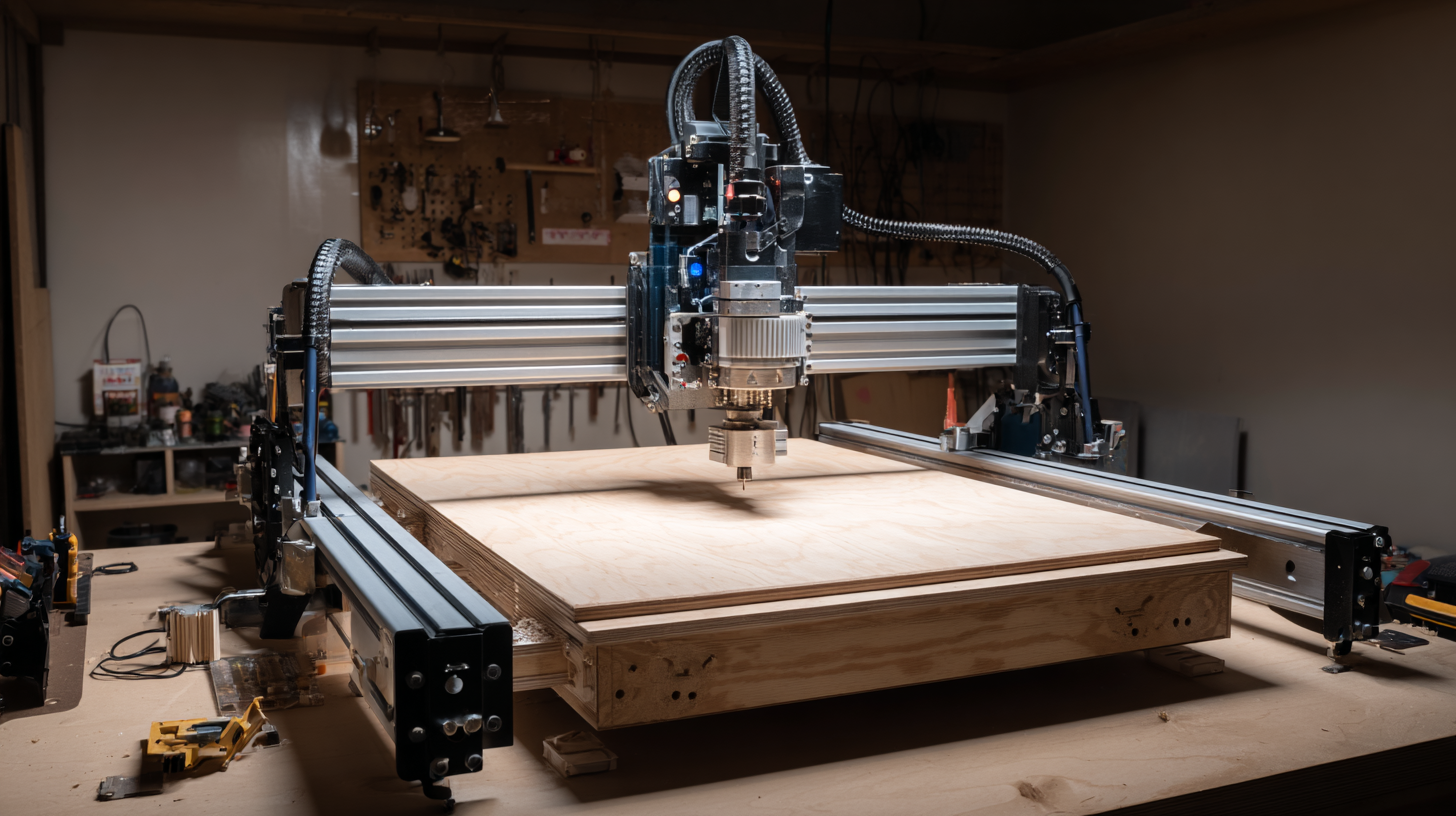

Key Features to Consider When Choosing the Best CNC Machine

When choosing the best CNC machine for your home shop, it's essential to consider several key features to ensure maximum efficiency. One of the first aspects to evaluate is the machine's size and work area.

Choose a CNC machine that fits your workspace while providing sufficient capacity for your projects. For smaller workshops, compact models might be ideal, while larger spaces can accommodate more extensive machines that offer greater versatility.

Choose a CNC machine that fits your workspace while providing sufficient capacity for your projects. For smaller workshops, compact models might be ideal, while larger spaces can accommodate more extensive machines that offer greater versatility.

Another critical feature is the machine's software compatibility. A user-friendly interface can significantly enhance your crafting experience, allowing for easier design uploads and modifications. Look for CNC machines that support various file formats and offer robust programming capabilities, enabling you to execute complex designs without steep learning curves.

Tip: Always check for the availability of support and resources specific to the CNC model you choose. Access to forums, tutorials, and customer service can greatly assist in troubleshooting and tips for maximizing your machine's potential. Additionally, consider the machine's material compatibility, ensuring it can handle the materials you plan to work with, whether wood, plastics, or metals.

Optimizing Your CNC Workflow for Increased Productivity

Maximizing efficiency in your CNC workflow requires a comprehensive approach that leverages real-time data to enhance production outcomes. By monitoring machine performance continuously, shop owners can detect tool breakages, surface anomalies, and other inefficiencies before they escalate into costly delays. This data-driven approach allows for just-in-time tooling adjustments and replacements, extending the life of cutting tools while ensuring optimal surface quality and consistency in output.

Moreover, integrating advanced CAD/CAM systems facilitates better management of production resources. By intelligently planning tool usage and maintaining a streamlined workflow, shops can minimize waste and reduce overall costs. The smart utilization of nesting and fabrication technologies allows users to refine their design processes, drastically increasing throughput while limiting inventory overhead. As manufacturers embrace these innovations, they are not only meeting the demand for higher precision but also setting the stage for a more productive and economically sustainable future in CNC machining.

Essential Tools and Accessories to Enhance Your CNC Experience

When it comes to enhancing your CNC experience, having the right tools and accessories is paramount. A home shop CNC machine is only as efficient as its operator, and equipping yourself with essential upgrades can significantly increase both functionality and precision. Consider investing in high-quality cutting bits and tooling accessories that cater specifically to the materials you're working with; this can make a substantial difference in the quality of your outputs. Moreover, incorporating software that is user-friendly and compatible with your CNC machine allows for smoother operation and design manipulation.

Additionally, don't overlook the importance of safety gear and workspace organization. As your CNC projects become more complex, having a designated safety kit—including goggles and gloves—becomes crucial. Likewise, keeping your workspace tidy and well-organized not only boosts efficiency but also minimizes the risk of accidents. Accessories like dust extractors and clamps can greatly enhance your work environment, making it easier to focus on the creative aspect of your projects. With the right tools and accessories, you can maximize the potential of your CNC machine and achieve impressive results tailored to your specific needs.

Top Strategies for Maximizing Efficiency with the Best Home Shop CNC Machine

Troubleshooting Common CNC Issues to Maintain Efficiency

When operating a CNC machine at home, maintaining efficiency often hinges on addressing common issues that may arise during production. According to a recent industry report by Statista, over 20% of CNC machine downtime is attributed to maintenance and troubleshooting errors. To mitigate this, it's crucial to implement a proactive maintenance schedule and regularly inspect the machine’s components.

**Tip:** Establish a weekly checklist covering threat assessments for tool wear and calibration checks. This practice not only preempts potential problems but can also extend the lifespan of your machine, as noted in a study by the National Tooling and Machining Association, which claims that regular maintenance can reduce downtime by up to 30%.

Another common issue is software errors that can halt production. A research report from SME revealed that incorrect tool paths accounted for 15% of total machine errors. To prevent these pitfalls, investing in updated software and training can significantly streamline operations.

**Tip:** Ensure all software updates are installed promptly and offer training sessions for all operators. Keeping everyone informed can drastically improve workflow and production efficiency, reinforcing a corporate culture of continuous improvement in your home shop.