Unlocking the Future of Manufacturing with Mill Turn Machines at 2025 China 138th Import and Export Fair

In the rapidly evolving landscape of manufacturing, the introduction and integration of innovative machinery such as the mill turn machine are instrumental in enhancing productivity and efficiency. According to a recent market analysis by Fortune Business Insights, the global machine tool market size is projected to reach approximately USD 100 billion by 2028, driven by advancements in automation and precision manufacturing. The mill turn machine, renowned for its capability to combine milling and turning processes into a single operation, is gaining traction among manufacturers seeking to streamline their production workflows.

As evidenced by the anticipated growth highlighted in the International Federation of Robotics report, which noted a 14% increase in the use of advanced robotics in manufacturing, the mill turn machine epitomizes the industry's shift towards more integrated and automated systems.

This year, at the 2025 China 138th Import and Export Fair, we will explore how mill turn machines can reshape the future of manufacturing, presenting opportunities for innovation and enhancing global competitiveness.

Revolutionizing Manufacturing: The Role of Mill Turn Machines

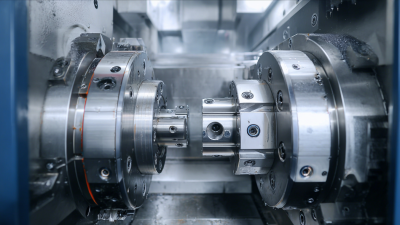

Mill turn machines are at the forefront of a manufacturing revolution, combining milling and turning capabilities in a single, powerful tool. This innovation allows manufacturers to achieve complex geometries and precision in a fraction of the time taken by traditional methods. The integration of advanced technology into these machines not only streamlines production processes but also reduces waste, enhancing overall efficiency. As showcased at the 2025 China 138th Import and Export Fair, mill turn machines exemplify the shift towards smarter, more adaptable manufacturing solutions that can meet the demands of a rapidly changing market.

The versatility of mill turn machines opens new avenues for industries ranging from aerospace to automotive. By enabling manufacturers to perform multiple operations without needing to switch between different setups or machines, these tools significantly cut down on cycle times and labor costs. Furthermore, their ability to incorporate automation and IoT technologies positions them perfectly for Industry 4.0, where data-driven decision-making and real-time monitoring play crucial roles. As we look toward the future of manufacturing, the role of mill turn machines will undoubtedly be pivotal in driving innovation and sustaining competitive advantage.

Innovative Technologies Showcased at the 2025 Import and Export Fair

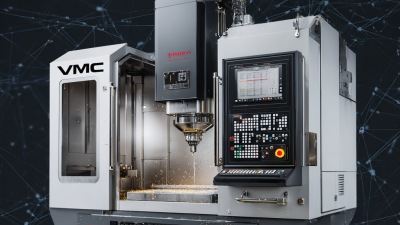

The 2025 Import and Export Fair is poised to showcase transformative innovations in manufacturing technology, with a particular emphasis on mill turn machines. According to a recent report by Technavio, the global market for CNC machines, which includes mill turn technology, is expected to grow by approximately 6.1% annually through 2025, driven by increased demand for precision engineering and automation across various industries. This fair will be an excellent platform for manufacturers to witness the future of machining, where efficiency and versatility take center stage.

Tips: When exploring the latest innovations at the fair, pay close attention to how mill turn machines can significantly reduce cycle times and production costs. These machines combine the capabilities of both milling and turning operations, allowing manufacturers to create complex parts in fewer setups, which is essential in an era where efficiency is key.

Moreover, the fair will feature a host of industry leaders demonstrating their cutting-edge technologies. Gillette Research suggests that companies that adopt advanced manufacturing technologies can increase productivity by up to 30%. This is a critical time for businesses to consider how they can leverage these innovations to stay competitive in the global market. Exploring partnerships and collaborations at the fair could unlock new avenues for growth and success.

The Benefits of Mill Turn Machines for Global Manufacturing Industry

Mill turn machines are revolutionizing the global manufacturing industry by offering unparalleled precision and efficiency. These advanced tools integrate both milling and turning capabilities, allowing manufacturers to produce complex parts in a single setup. This consolidation not only reduces production time but also minimizes the potential for errors that often occur in multi-step processes. As a result, businesses can significantly enhance their operational efficiency and reduce costs while maintaining high-quality standards.

Moreover, the adoption of mill turn machines promotes flexibility in manufacturing. Companies can easily adapt to changing market demands and customize products more swiftly. This responsiveness is crucial in today’s fast-paced economy, where customer preferences are constantly evolving. Furthermore, the sustainability aspect of mill turn machines cannot be overlooked; they help in minimizing waste and optimizing material usage, contributing to eco-friendly manufacturing practices. As manufacturers showcase these innovations at the 2025 China Import and Export Fair, the potential impact on the global industry becomes even more apparent.

Unlocking the Future of Manufacturing with Mill Turn Machines at 2025 China 138th Import and Export Fair - The Benefits of Mill Turn Machines for Global Manufacturing Industry

| Application Area | Efficiency Improvement (%) | Cost Reduction (%) | Cycle Time Reduction (%) | Flexibility Rating (1-5) |

|---|---|---|---|---|

| Aerospace | 20 | 15 | 25 | 4 |

| Automotive | 30 | 20 | 15 | 5 |

| Medical Devices | 25 | 10 | 20 | 3 |

| Electronics | 35 | 18 | 30 | 4 |

| Energy | 15 | 5 | 10 | 3 |

Networking Opportunities for Manufacturers at the 138th China Fair

The 138th China Import and Export Fair presents an exceptional platform for manufacturers to forge meaningful connections and explore collaborative opportunities. Networking at this prestigious event allows industry leaders, innovators, and emerging businesses to come together, facilitating the exchange of ideas and best practices. With the rapid advancement in manufacturing technologies such as Mill Turn machines, participants have the chance to learn from one another, share insights, and discuss the future direction of the industry.

Manufacturers attending the fair will benefit not only from direct interactions with potential partners and clients but also from a plethora of seminars and workshops focusing on the latest trends and technologies. This engagement is crucial for staying competitive in the evolving market landscape. Emphasizing on the applications and advantages of Mill Turn machines, attendees can glean valuable knowledge that may enhance their operational efficiencies and product offerings, ensuring they are well-equipped to meet future demands. The networking opportunities at the 138th China Fair are poised to unlock new avenues for innovation and growth within the manufacturing sector.

Future Trends in Manufacturing and Mill Turn Machine Adoption

The manufacturing landscape is rapidly evolving, and the adoption of mill turn machines is at the forefront of this transformation. As industries seek greater efficiency and precision, mill turn machines allow for the seamless execution of both milling and turning operations within a single setup. According to a report by MarketsandMarkets, the global market for mill turn machining is projected to reach USD 5.8 billion by 2025, growing at a CAGR of 7.5%. This growth highlights the increasing reliance on these advanced machining solutions to meet the demands of modern manufacturing.

The 2025 China 138th Import and Export Fair serves as a platform to showcase this shift towards integrated manufacturing technologies. With manufacturers aiming for leaner operations, the multi-functionality of mill turn machines translates into reduced setup times and minimized waste. A survey by Deloitte reveals that 61% of manufacturers are investing in advanced technologies to enhance production capabilities. The rise in automation and digitalization trends further supports the case for adopting mill turn machines, making them indispensable for future-ready manufacturing environments.

Related Posts

-

2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers

-

Understanding the Benefits of Mill Turn Machines for Efficient Global Manufacturing Strategies

-

Exploring the Future of Precision Manufacturing: Best CNC Lathe and Milling Machines for Global Buyers

-

How to Choose the Best Micro CNC Milling Machine for Your Needs

-

How to Choose the Right Metal CNC Machine for Your Business Needs

-

Solutions for Selecting the Best VMC Milling Machine for Your Manufacturing Needs