Discover World-Class Manufacturing: Elevate Your Production with the Best CNC Turning Machine from China

In today's competitive manufacturing landscape, staying ahead requires not only advanced technology but also the right equipment to enhance production efficiency and precision. One such powerhouse in the realm of manufacturing is the CNC turning machine, a marvel of engineering that has transformed how industries approach their production needs.

With the capabilities to create complex designs with remarkable accuracy, these machines are essential for businesses aiming to elevate their operations to a world-class standard. As we explore the advantages of sourcing CNC turning machines from China, we will uncover how they can significantly improve your production processes, reduce costs, and ultimately lead to higher quality outputs. Join us on this journey to discover how investing in the best CNC turning machines can revolutionize your manufacturing capabilities.

With the capabilities to create complex designs with remarkable accuracy, these machines are essential for businesses aiming to elevate their operations to a world-class standard. As we explore the advantages of sourcing CNC turning machines from China, we will uncover how they can significantly improve your production processes, reduce costs, and ultimately lead to higher quality outputs. Join us on this journey to discover how investing in the best CNC turning machines can revolutionize your manufacturing capabilities.

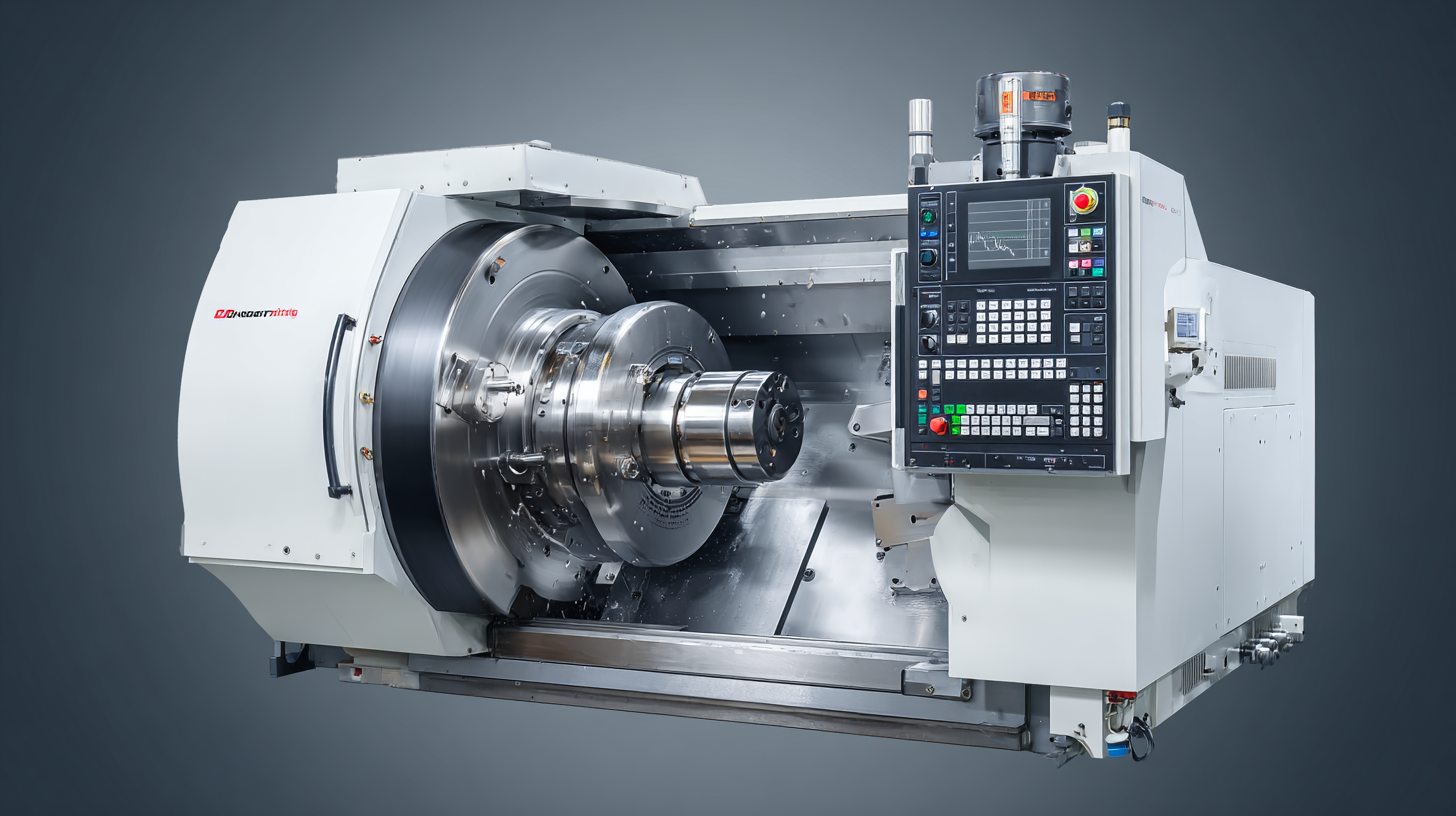

Key Features to Look for in a Top CNC Turning Machine

When selecting a top-tier CNC turning machine, several key features stand out that can significantly enhance your manufacturing capabilities. First and foremost, consider the machine's precision and accuracy. A high-quality CNC lathe should boast minimal runout and tight tolerances, allowing for consistent and reliable production of complex components. Look for machines equipped with advanced feedback systems and high-resolution encoders, which enable real-time monitoring and adjustments during the turning process.

Another vital feature to assess is the machine's versatility and tooling options. A top CNC turning machine should support various materials—such as metals, plastics, and composites—and offer a range of tooling configurations. This adaptability not only caters to diverse production needs but also ensures that manufacturers can respond swiftly to market demands. Additionally, consider the machine's software capabilities; a user-friendly interface and robust programming features can streamline operations and reduce setup times, ultimately leading to increased productivity and efficiency in your production line.

Understanding the Benefits of CNC Turning in Manufacturing

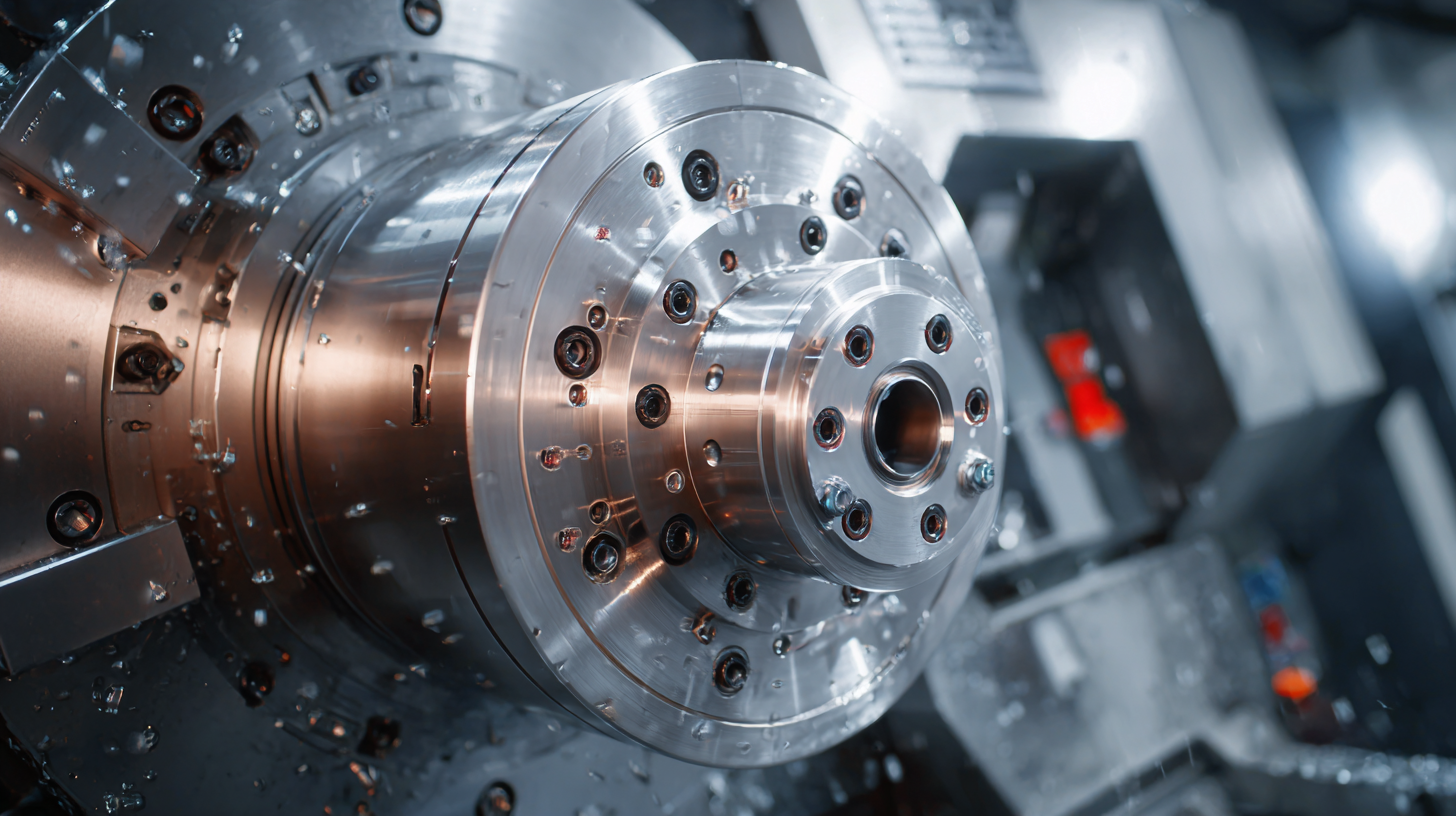

CNC turning has revolutionized the manufacturing landscape by significantly enhancing precision, efficiency, and productivity. According to a report by Research and Markets, the global CNC lathe market is expected to grow at a CAGR of 4.3% from 2021 to 2026, reaching USD 1.99 billion by 2026. This growth underscores the demand for advanced manufacturing techniques that not only reduce operational costs but also ensure high-quality production results.

One of the key benefits of CNC turning is its capability to produce highly intricate components with minimal human intervention. The automated nature of CNC turning reduces the risk of errors significantly, leading to less waste and higher accuracy. Industry data shows that manufacturers utilizing CNC technology can achieve a 60% reduction in setup time while enhancing production speed by up to 50%. Additionally, CNC turning allows for complex designs that were once impossible with traditional methods, enabling companies to remain competitive in a fast-paced market.

Furthermore, CNC turning machines from China are increasingly recognized for their cost-effectiveness without compromising quality. A report by Statista highlighted that China's manufacturing sector is projected to contribute USD 4.66 trillion to the global economy by 2030, showcasing the country's pivotal role in advancing manufacturing technologies. Investing in the best CNC turning machines can be a game-changer for manufacturers looking to elevate their production capabilities and meet the growing demands of the market.

Comparative Analysis: Best CNC Turning Machines from China

When it comes to manufacturing precision parts, selecting the right CNC turning machine is crucial for productivity and quality. A comparative analysis of the best CNC turning machines from China reveals significant variations in features, pricing, and capabilities. According to a recent industry report by Research And Markets, the global CNC machine market is projected to reach $117 billion by 2026, showcasing the growing reliance on automated solutions in various sectors. Machines from top Chinese manufacturers are distinguished not only by cost-effectiveness but also by their advanced technology, offering exceptional reliability and precision for high-volume production.

**Tip 1:** Always assess the machine’s specifications, such as spindle speed, tool capacity, and automation features, to ensure it meets your production requirements effectively. A machine with a higher spindle speed could drastically reduce cycle time and increase output.

Another key consideration is after-sales support. A study by MarketsandMarkets indicates that strong service networks are crucial for manufacturers, affecting equipment uptime and overall operational efficiency. The best CNC turning machines from China often come with robust warranties and comprehensive customer service, making them a wise investment for sustained operations.

**Tip 2:** When comparing options, research the manufacturer’s reputation for post-purchase support. Engaging with current users through forums or industry groups can provide valuable insights into their experiences with machine reliability and service quality.

Comparative Analysis of CNC Turning Machines from China

This chart presents a comparative analysis of various CNC turning machines based on their cutting speed and maximum spindle power. The data suggests a range of performance metrics, which are essential for manufacturers in selecting the best machine for their production needs.

Tips for Selecting the Right CNC Turning Machine for Your Needs

When selecting the right CNC turning machine for your production needs, several factors come into play. First and foremost, assess the specific requirements of your projects. Consider the size, material, and complexity of the parts you will be manufacturing. This will help you determine the necessary specifications for your CNC machine, such as spindle speed, torque, and capabilities for various materials. Understanding your production needs ensures you choose a machine that can handle your workflow efficiently.

Another critical aspect to consider is the machine's technology and features. Modern CNC turning machines often come equipped with advanced software that can improve precision and efficiency. Look for models that support automation, offer user-friendly interfaces, and provide options for customization. Additionally, pay close attention to the machine's construction quality and durability, as investing in a reliable CNC turning machine will pay off in the long run by minimizing maintenance costs and downtime. By carefully evaluating these factors, you can select a CNC turning machine that elevates your production capabilities and meets your business goals.

Discover World-Class Manufacturing: Elevate Your Production with the Best CNC Turning Machine from China

| CNC Turning Machine Feature | Specification | Importance | Recommended For |

|---|---|---|---|

| Max Swing Diameter | 500 mm | Allows machining of larger workpieces | Aerospace, Automotive |

| Spindle Speed | 4000 RPM | Ensures efficient material removal | Manufacturing, Prototyping |

| Number of Axes | CNC 3 axes | Provides versatility in machining | General Manufacturing |

| Control System | Siemens / Fanuc | Enhanced programmability and ease of use | Precision Machining |

| Tool Storage Capacity | 24 tools | Reduces tool change time | Complex Parts Manufacturing |

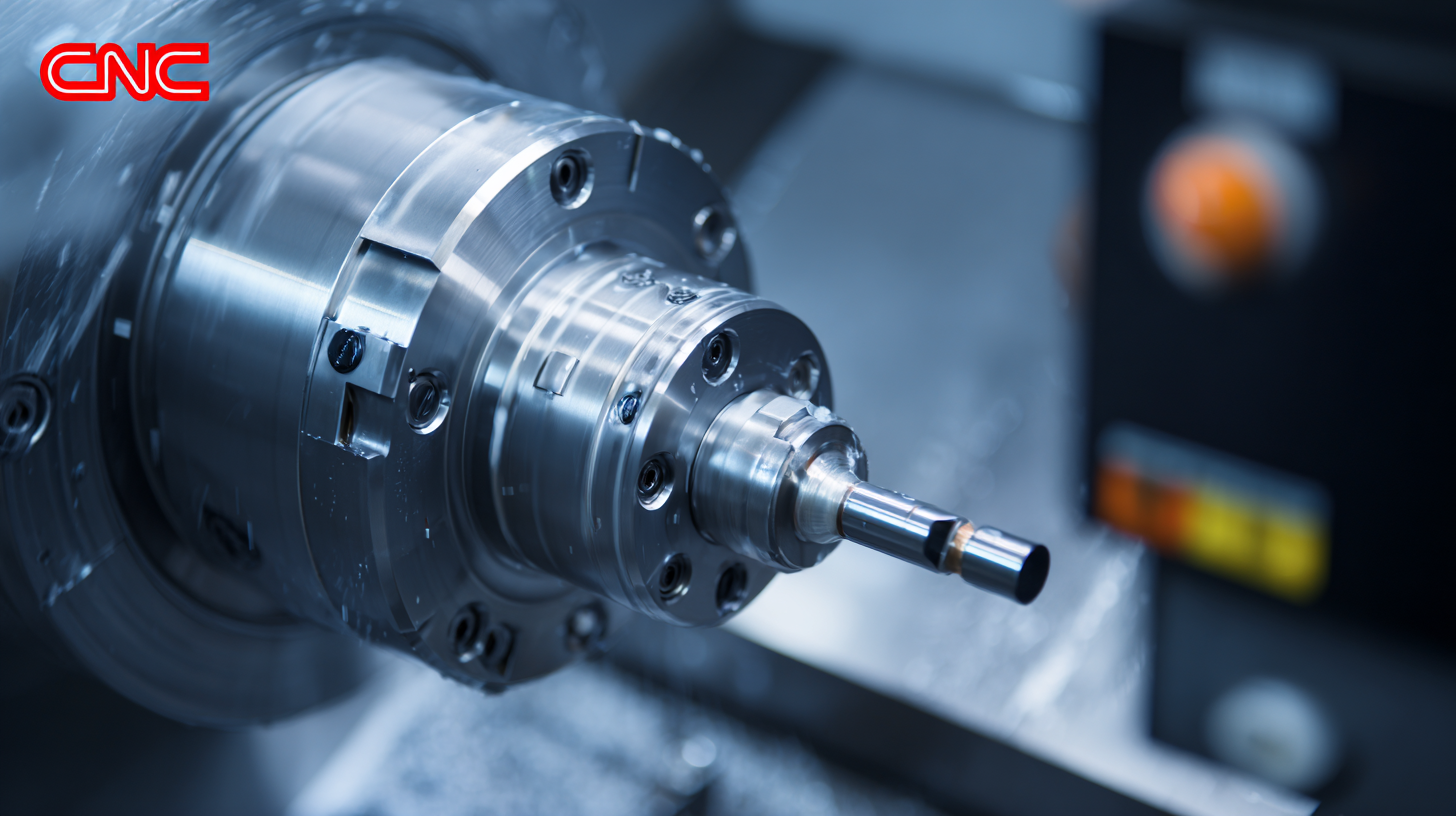

Maximizing Production Efficiency with Advanced CNC Turning Technologies

In today's competitive manufacturing landscape, maximizing production efficiency is paramount. Advanced CNC turning technologies offer unparalleled precision and speed, allowing businesses to streamline their operations and significantly reduce waste. By investing in state-of-the-art CNC turning machines from China, manufacturers can enhance their productivity while maintaining high quality standards. These machines are equipped with cutting-edge features that enable quick changeovers, automated setups, and improved cycle times.

Tip 1: To fully leverage the capabilities of CNC turning machines, consider implementing regular maintenance schedules and operator training. This can prolong machine life and optimize performance, ensuring that your production line runs smoothly.

Integrating advanced CNC turning technologies not only boosts efficiency but also provides opportunities for innovation in product design. With the capability to produce complex geometries, manufacturers can explore new product lines that cater to diverse market needs.

Tip 2: Experiment with different materials and cutting tools to find the best combination for your specific production requirements. This experimentation can lead to unexpected improvements in both quality and efficiency, ultimately benefiting your bottom line.